- Joined

- Dec 31, 2010

- Messages

- 937

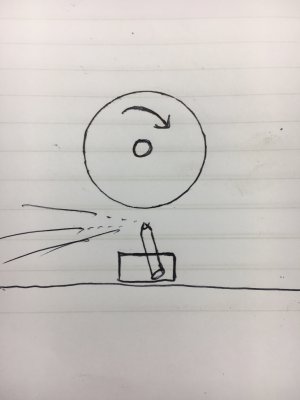

I have a small round industrial diamond dresser that I have never used and now need to dress the leading corner on a 5 1/2" cup grinding wheel. Just guessing I need to remove a piece of Aluminum oxide that is about 1/16"deep X 1/4" wide around the stone. My question is:: What is the correct angle to hold the 1/2" X 1 1/4" diamond dressing holder. The point on the tool is a 90` cone and my thinking is it should be similar to a HSS cutting tool where there is a lot of strength directly under the point of contact. I believe I can make a sturdy holder for the job but I am at a loss on how the diamond cutter should approach the stone. All help will be appreciated.

Have a good day

Ray

Have a good day

Ray