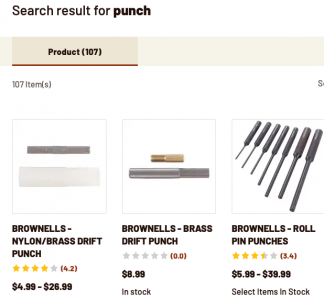

I was never taught to use drift punches. I've used parallel pin punches and roll pin punches and line up punches, but never drift punches.

As I understand it the drift punch was used to bust a pin loose before removal with a pin punch. Is that their primary use?

Do you go straight to a pin punch or do you use a drift punch? Thoughts?

As I understand it the drift punch was used to bust a pin loose before removal with a pin punch. Is that their primary use?

Do you go straight to a pin punch or do you use a drift punch? Thoughts?