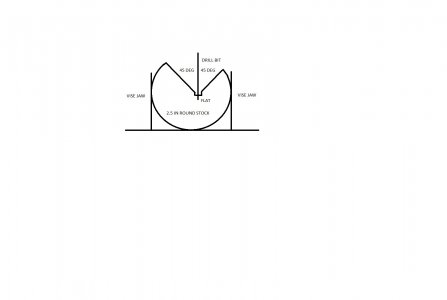

... bisecting the 90 degree angle perfectly, in round stock (see the pic below)? I see it as two issues:

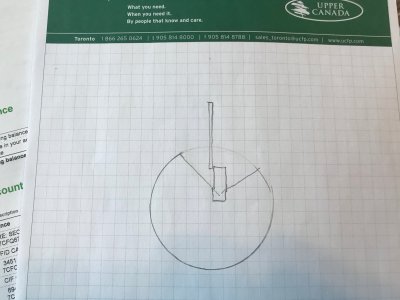

1. Rotating the round stock so the V-notch is perfectly symetrical about the vertical. Note the V-notch is offset from the center of the round stock.

2. Aligning the spindle of the milling machine exactly with the notch.

I can imagine using the 45 degree side of a machinist square for rotating the round stock, perhaps non-accurately, but aligning the spindle with the notch is a stumper. The milled flat spot is for starting the drill bit.

Any ideas?

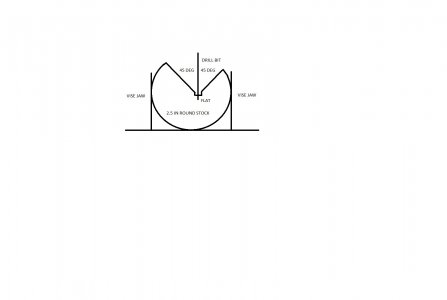

1. Rotating the round stock so the V-notch is perfectly symetrical about the vertical. Note the V-notch is offset from the center of the round stock.

2. Aligning the spindle of the milling machine exactly with the notch.

I can imagine using the 45 degree side of a machinist square for rotating the round stock, perhaps non-accurately, but aligning the spindle with the notch is a stumper. The milled flat spot is for starting the drill bit.

Any ideas?