I purchased two drill presses at an auction and neither of them have good motors. I would like to try to repair them, but i don't know jack diddley about motors. I have looked for a trouble shooting guide online, but i haven't found anything good. Perhaps y'all can help me out.

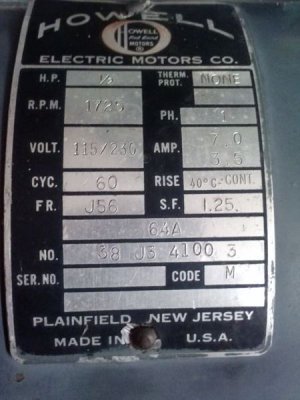

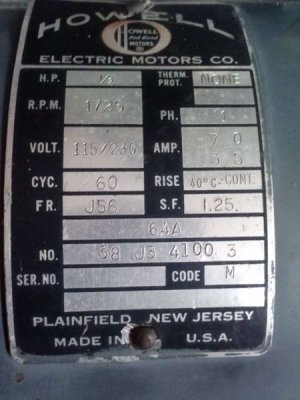

Motor 1:

120V 1PH

motor buzzes and will not start even if spun by hand. motor spins freely when off

Motor 2:

220v 3ph

starts and works, but pulls over 2x the current it should according to my VFD. It also gets very hot. Seems to have good torque and work fine other then it getting hot.

Any hope for these?

Josh

Motor 1:

120V 1PH

motor buzzes and will not start even if spun by hand. motor spins freely when off

Motor 2:

220v 3ph

starts and works, but pulls over 2x the current it should according to my VFD. It also gets very hot. Seems to have good torque and work fine other then it getting hot.

Any hope for these?

Josh