- Joined

- Jan 22, 2017

- Messages

- 104

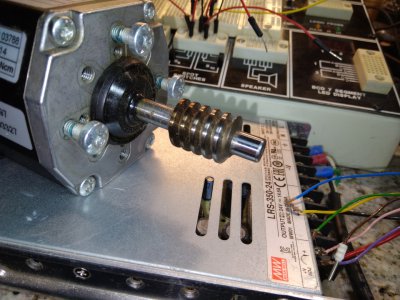

I picked up a Dunkermoteren BG-65 with the intent of replacing the motor on my Unimat SL1000. The motor works great on the bench, however I'm now looking to remove the worm from the shaft. I've tried a bit of force using a puller but am shying away from violence at this point.

I'm thinking that maybe they used one of various adhesive products that I MIGHT be able to use heat to break the bond.

So I figured it would be safer at this point to put the question out to the group and see if anyone here has had any experience with with these or similar.

Thanks

I'm thinking that maybe they used one of various adhesive products that I MIGHT be able to use heat to break the bond.

So I figured it would be safer at this point to put the question out to the group and see if anyone here has had any experience with with these or similar.

Thanks