Hi

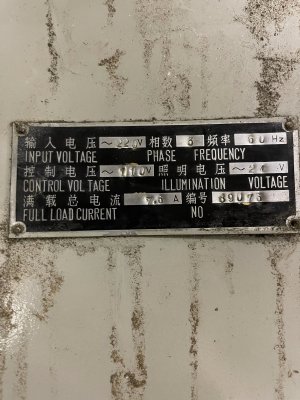

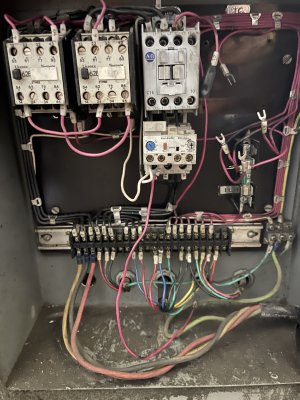

Im looking for information on an Edison 1340gh lathe. specifically electrical information. If anybody has an owners manual with a wire diagram that would be awesome! or even just a picture of the electrical panel in the back of the lathe.

From what i understand this lathe was manufactured by DAR SIN and they sold the lathe under several different names. (DSL 1340gh) I recently aquired this lathe and would love to work past the electircial issues and get it running.

thank you

Im looking for information on an Edison 1340gh lathe. specifically electrical information. If anybody has an owners manual with a wire diagram that would be awesome! or even just a picture of the electrical panel in the back of the lathe.

From what i understand this lathe was manufactured by DAR SIN and they sold the lathe under several different names. (DSL 1340gh) I recently aquired this lathe and would love to work past the electircial issues and get it running.

thank you