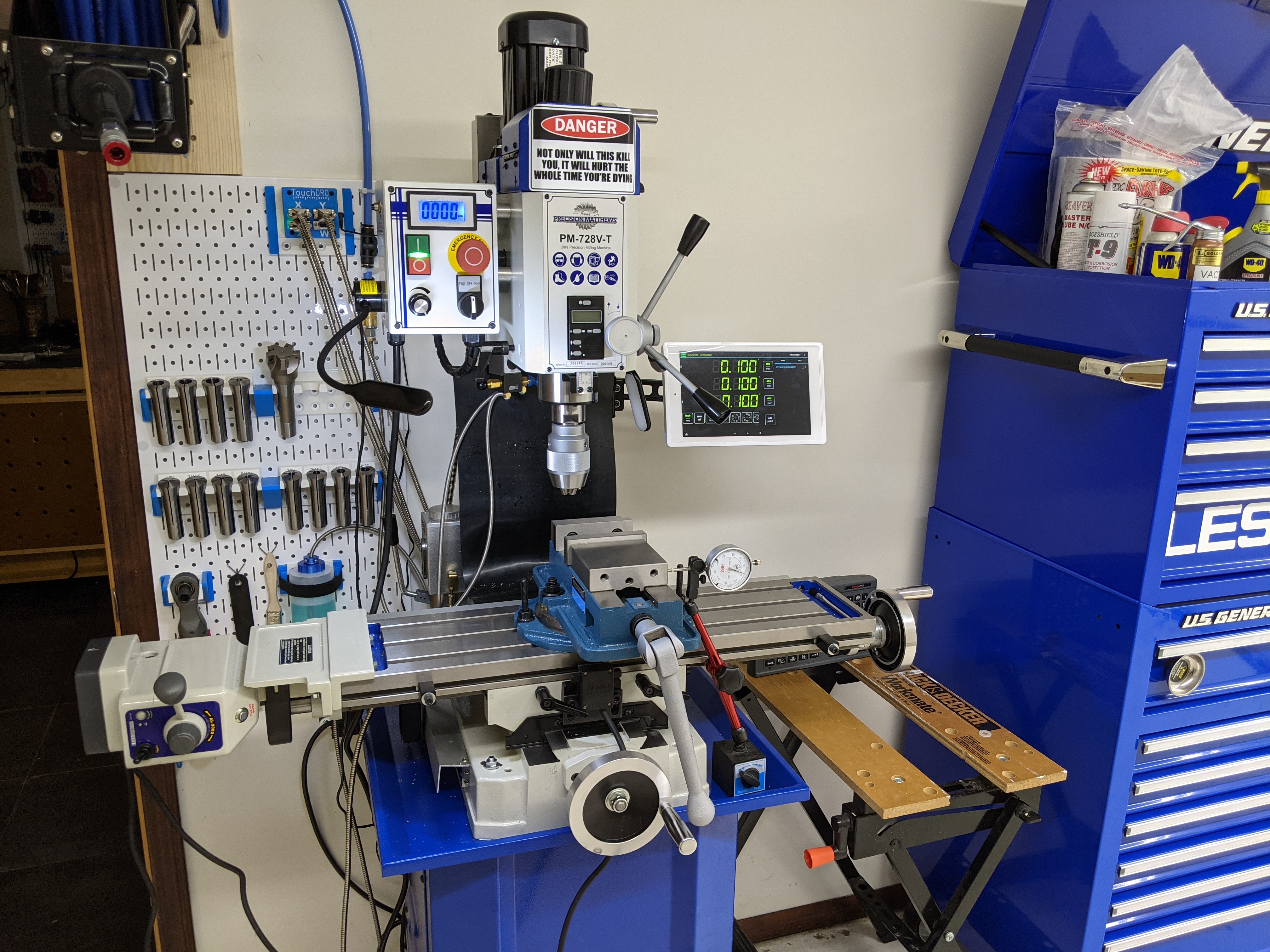

I've been looking into this and I think the deal is that the serial communication capability is an optional feature. I recently purchased a 728VT and it came with the EL403-M v5 DRO.

As others have noted, this device is made by Electronica Mechatronic Systems and the USB vendor ID "1D32" aligns with that.

The product page for this device shows several variants. There's the "EL403-M 3 Axes Mill" which is what PM appears to be sending out, and there's the "EL413-M 3 Axes Mill with Options" model which I suspect is what we need in order to enable the serial output. The manual labels that port as "15-Pin D-Type Female For Auxiliary Output (Optional)". As noted, there is no guidance in the manual as to where one might be able to connect via serial, but I think it's likely intended to be accessed from the DSub15 option port, and also suggests that option port is only available on models listed as "with options".

According to

the manual, the option output might have a couple different pinouts depending on the specific model in use. The EDM variant should have the following pinout:

View attachment 361562

While models "with options" have the following pinout:

View attachment 361564

Pins 5,7,8,13, and 14 are unused in both, which might be likely candidates for the serial capability.

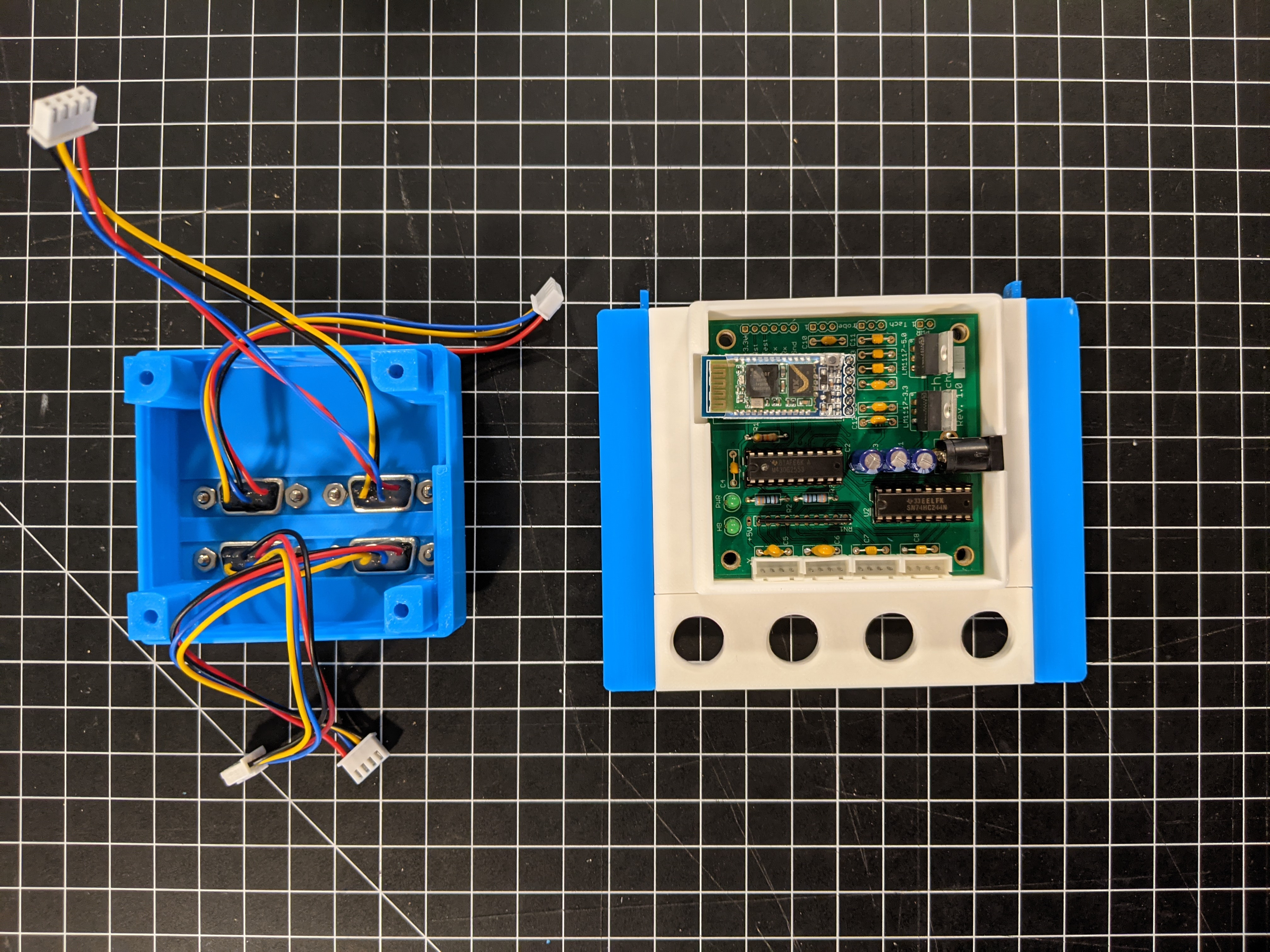

Inside the device we can take a look at the IO PCB which has the various connectors and supporting components that face the back of the device.

Rear:

View attachment 361565

Front:

View attachment 361566

This board has two ribbon cables (one disconnected in the photo above) which both connect to the main controller board. Going back to our list of unaccounted for pins, visually I find the following:

| Pin | Connection |

| 5 | Ribbon J2 to main PCB |

| 7 | NC |

| 8 | Power (connects to red/black cable and fuse F1) |

| 13 | Ribbon J2 to main PCB |

| 14 | Bridged to pin 15 (SW- for EDM variants) |

There are also several unpopulated footprints near this port, which might mean that the necessary components for serial output are not present. However, based on the table above, I think pins 5 and 13 might be good starting points for investigation.

I have some PCB mount DSub 15 connectors on order and will solder those in place which will make this hunt a little easier.