- Joined

- Jan 2, 2019

- Messages

- 6,524

<snip>

I guess what I'm saying is that if you want to build one now, you can without needing to wait on anything.

That's what I gathered from Github.

Pictures of what you've done?

<snip>

I guess what I'm saying is that if you want to build one now, you can without needing to wait on anything.

That's what I gathered from Github.

Pictures of what you've done?

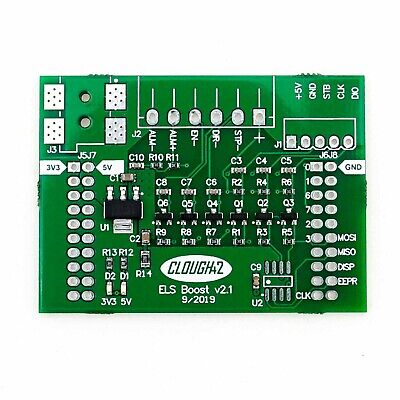

I probably have about $350 into the Clough42 build end-to-end, with about $300 of that being the pulleys, belts, servo, driver, encoder and power supply. Those costs will have to be added on to the Rocketronics unit as well, so it does add up.well... sort of. Matching the driver boards to the steppers, and to the logic board isn't a slam dunk. In the sense that you can buy and entire kit from Rocketronics, it makes the procurement part a one-stop-shop. The Clough42 solution would be a LOT cheaper, but I just don't want the uncertainty of doing it myself. I'm not really worried about reliability and fixing: the Rocket solution has a very good rep, and good customer service.

I'm not totally decided yet, but at the moment I'm leaning that way. If the Clough42 option seems more like what I'm okay with, then I'll probably go that way instead. I've got time to wait and see how things fall out.

wow thanks Jon, glad to "meet". Thanks for the detailed reply - it takes time to draft something logically, so appreciate your time spent very much. EXCELLENT work & love the tidy background shots of your shop! (You are not gunna see mine!! - yet).You found me. I don't have any backlash compensation because it's not CNC, just a programmable "gearbox". The number of pitch selections is arbitrary. I've implemented every pitch that I could find in online pictures of lathes, and every tap available from McMaster-Carr. I stopped short of having an arbitrary programmable option, but it would be possible. I did limit it to 4tpi just because I have a small lathe. That's getting to be some serious depth of cut, and I have already noticed some "hiccups" cutting an 8tpi Acme thread in 1144. I'm waiting for more timing pulleys and belts so that I can gear it down from the current 4:1 ratio between the stepper and the screw. I'm planning to test it at 5-, 6- and 8-to-1.

I still have more to do. The touch screen is great for a lot of things, but on-the-fly feed direction control needed something more tactile, so I've added a toggle switch mounted in front of the headstock. I quickly programmed it to control the direction, but have to add jogging support still. I just got sidetracked by actually making some things.

I think it would be cool to do cut knurling, so I'm also thinking of adding support for multi-start threads, but that's a ways off yet. I've only used half the RAM on the Mega so far, so there's still room to squeeze more features in. I promise to make at least a basic version of the code available at some point when I'm satisfied with it.

-Jon

I would be interested in your comments, Dabbler, on my comparisons, summary, presented to Jon, Briney Eye re ELS, in particular Wade'O design's efforts, scope of ELS stand alone part of his design. BTW thanks for your comment re Rocketronics good customer service.well... sort of. Matching the driver boards to the steppers, and to the logic board isn't a slam dunk. In the sense that you can buy and entire kit from Rocketronics, it makes the procurement part a one-stop-shop. The Clough42 solution would be a LOT cheaper, but I just don't want the uncertainty of doing it myself. I'm not really worried about reliability and fixing: the Rocket solution has a very good rep, and good customer service.

I'm not totally decided yet, but at the moment I'm leaning that way. If the Clough42 option seems more like what I'm okay with, then I'll probably go that way instead. I've got time to wait and see how things fall out.