I have read this (see below) but the person did not say what wires to put the cap onto. This seems like a way to keep the soft start but eliminate the zero start. And it sounds like it might work for any treadmill motor controller. I am using this in a drill press. I need to keep the set speed between holes. Thank You.

This is the copy from someones else's post.

"I have developed a simple way to bypass the MC60 motor controller requiring returning to zero speed before starting.

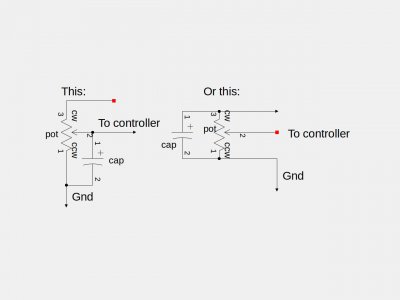

Simply place a 100uF/50v cap between the black and white terminals with the negative leg on the black.

The cap acts as a temporary short, simulating turning the speed to zero. Now you can set the speed, turn it off, turn it back on without changing the speed setting."

This is the copy from someones else's post.

"I have developed a simple way to bypass the MC60 motor controller requiring returning to zero speed before starting.

Simply place a 100uF/50v cap between the black and white terminals with the negative leg on the black.

The cap acts as a temporary short, simulating turning the speed to zero. Now you can set the speed, turn it off, turn it back on without changing the speed setting."