mksj: thanks for the input. The nameplate on mine is a 50VA and I've been looking at them. Ebay has a lot of options but the ones I've looked at do not have dimensions - and that's important due to the space in the box.

I want to make sure I understand the wiring on the new ones. My current transformer has 2 110v wires coming into the primary (top) terminals - when it was working.

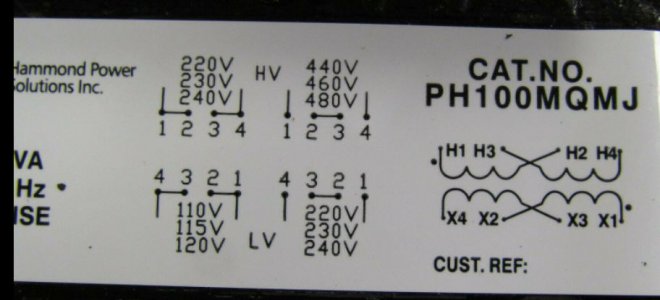

On the nameplate of the New Hammon, do I understand it correctly to mean this:

On the primary (top) side where the nameplate says 220v, 230v, 240, connect one of the top terminal wires from the old transformer (which is 110v) to terminal 1, and the other top 110v wire to terminal 4, bridging 1 & 2 and 3 & 4. Then on the bottom secondary side, connect the 2 wires that are on the bottom side of the old transformer to the terminals 4 & 1 - with 4&3 bridged and 2&1 bridged.

I just want to be sure I'm interpreting it properly.

Thanks