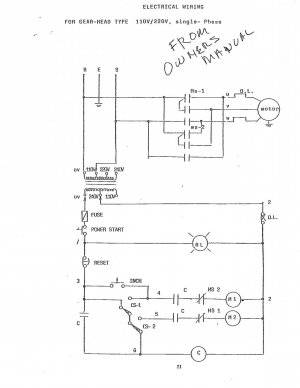

I have a problem with an Enco 12/36 model 110-2031 built 1991 serial 4257 bench lathe where there is a delay in the machine stopping when is turned off from the apron.

It can take several minutes to go off and the emergency stop also will not turn it off. Reverse works fine, emergency stop also works when in reverse. It has been like this since new and at times it works fine. The fact the emergency stop does not work really puzzles me.

I tried metering the apron switches they seem to be OK the stop button also seems to be OK. I had someone look at it that Enco recommended to no avail.

Has anyone had a problem like this or suggest where to look.. The EPO switch has to be a clue to what is wrong, but I cannot figure it out.

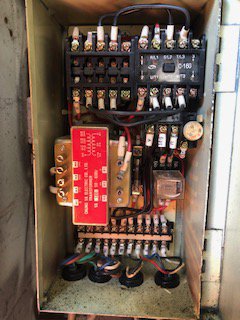

The device with a white knob I assume is an overload protection. Below that is a small relay I call the control relay. One leg has what appears to have a diode on it.

It can take several minutes to go off and the emergency stop also will not turn it off. Reverse works fine, emergency stop also works when in reverse. It has been like this since new and at times it works fine. The fact the emergency stop does not work really puzzles me.

I tried metering the apron switches they seem to be OK the stop button also seems to be OK. I had someone look at it that Enco recommended to no avail.

Has anyone had a problem like this or suggest where to look.. The EPO switch has to be a clue to what is wrong, but I cannot figure it out.

The device with a white knob I assume is an overload protection. Below that is a small relay I call the control relay. One leg has what appears to have a diode on it.