Another newbie question. I have an older LeBlond lathe that has a LO spindle. I do have a 3 & 4 jaw chuck for the lathe. I also have a Bridgeport J head mill. I am thinking of getting ER 32 collets so I can use them both on the lathe and mill. However, I am not sure if I can even get an ER collet chuck for my lathe. Options?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ER 32 Collet Chuck

- Thread starter Scruffer

- Start date

- Joined

- Apr 30, 2015

- Messages

- 11,333

What is the inner taper of your lathe spindle? Is it Morse? There are Morse to ER chucks available.

However if you wanted to pass stock all the way through I'm not sure what is available

for an LO spindle nose- perhaps an LO backplate plus a flatback ER collet chuck? Some machining

obviously would be required

However if you wanted to pass stock all the way through I'm not sure what is available

for an LO spindle nose- perhaps an LO backplate plus a flatback ER collet chuck? Some machining

obviously would be required

- Joined

- May 4, 2019

- Messages

- 792

There are flange mount ER collet chucks available. You just need to make a backplate to adapt one to your lathe.

- Joined

- Jun 7, 2013

- Messages

- 10,104

Or get a flange mount collet nose that takes 5C collets.

- Joined

- Jan 4, 2021

- Messages

- 1,819

Unless (and even if you do) already have ER32 collets for your mill, I’d recommend getting ER40 for the additional capacity - every additional mm of capacity will help one day.

And I second getting a flange mount so you can hold longer stock.

And I second getting a flange mount so you can hold longer stock.

Thanks everyone. I am taking the advice and going with the flange collet chuck (ER 40) and using a backplate for my lathe (LO spindle). ER 40 collets also. My project right now is fabricating 1.000" OD x 4.000" AL 6061 round bar. Threaded on both ends 1/2 - 13 UNC 1" depth. Also doing the same with .750" & .375 round bar. 1/4 - 20 UNC & 10-32 threads accordingly. 50 pieces for each.

- Joined

- Dec 12, 2016

- Messages

- 497

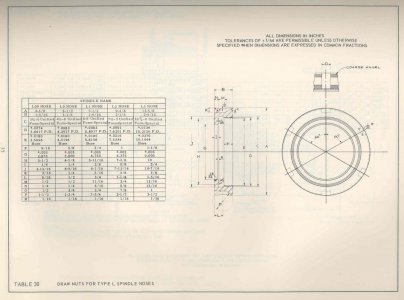

Attached is an example of a ER32 chuck mounted to a modified commercial L00 backplate for use on my Clausing.

If you use a registering flange arrangement, leave a couple of thousands clearance, and once mounted you can pump it around to get the last bit of runout out. The tapered spindles seem to introduce about .001 of possible runout when remounting things.

If you use a registering flange arrangement, leave a couple of thousands clearance, and once mounted you can pump it around to get the last bit of runout out. The tapered spindles seem to introduce about .001 of possible runout when remounting things.

Attachments

Great pic. Since my spindle is L-0, I probably need to use the larger flange mounted collet chuck (3901-5038) for the ER 40. The supplier looks to be HHiP. Amazon has it. It comes with the wrench. So, my next newbie question, can I use a low friction nut on the collet chuck? Are the threads standard? ThksAttached is an example of a ER32 chuck mounted to a modified commercial L00 backplate for use on my Clausing.

If you use a registering flange arrangement, leave a couple of thousands clearance, and once mounted you can pump it around to get the last bit of runout out. The tapered spindles seem to introduce about .001 of possible runout when remounting things.