- Joined

- Nov 23, 2014

- Messages

- 2,623

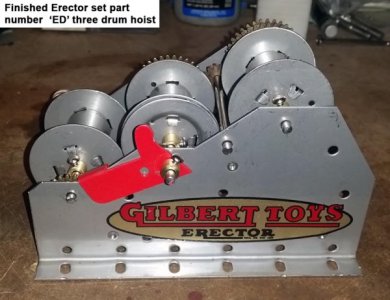

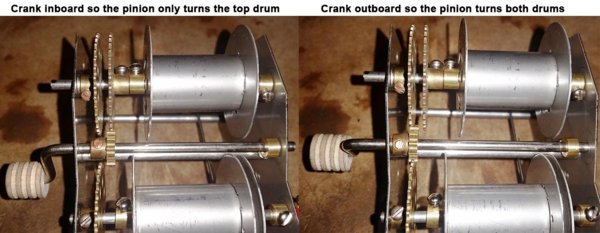

Here’s another thread of an Erector set part reproduction. This one is Gilbert Erector set part number ‘ED’, the triple drum hoist. First the obligatory history lesson . . . Gilbert introduced this part to the Erector set line in 1927 and included it in sets (just the largest two sets, size No. 8 and No. 10) in 1927. The gearing in the hoist can be set up in different ways. For the most part, the hoist was set up with two ‘CJ’ 36-tooth gears on the upper drum and one ‘CJ’ 36-tooth gear on the middle drum. The upper crank had a ‘P12’ 12-tooth pinion gear on it which engaged either both ‘CJ’ gears on the upper and middle drums, or just one ‘CJ’ on the upper drum. This was achieved by sliding the crank back/forth in the side plate holes. The middle drum has a friction brake of sorts to keep it from free-wheeling when the crank pinion is disengaged from its 36-tooth gear.

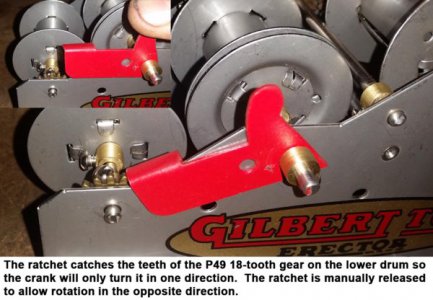

The lower crank has a ‘P49’ 18-tooth gear on it which engages with a ‘BF’ ratchet. The ratchet edge jams into the 18-tooth gear and allows the crank to only turn in one direction. The child would have to manually release the ratchet by pulling back on a finger catch to turn the drum the opposite direction.

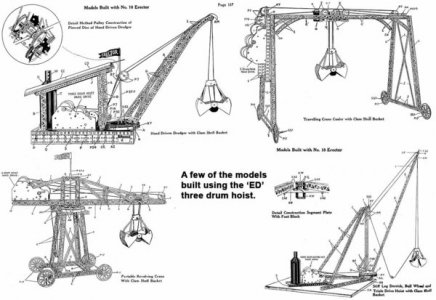

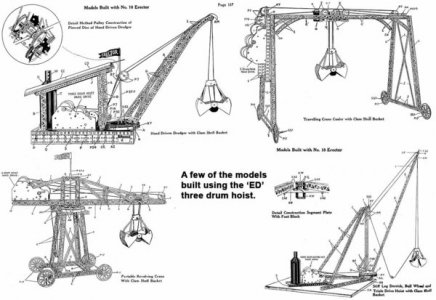

Gilbert illustrated a number of crane models that used the ‘BM’ clam shell bucket and ‘ED’ hoist. The clam shell bucket had a counterweight, which when raised or lowered relative to the bucket itself opened or closed the bucket. Perfect application for the ‘ED’ hoist and the upper two drums. The upper drum was strung to the counterweight and the middle drum to the clam shell itself. The child could slide the upper crank to engage just the upper drum, then turn the crank in either direction to open or close the bucket. Then slide the crank so both drums were engaged, then turn the crank to raise or lower the bucket with the bucket opening staying put. The lower drum was strung to a crane boom. Turning the crank without pulling back on the ratchet raised the boom. The child would grab the lower crank, pull back on the ratchet, and turn the crank to lower the boom.

You’d think that the ‘ED’ being in just two large sets (a very nice 1927 No. 10 set sold at auction for $17,000 in 2006) that there wouldn’t be a lot of demand for it. Well, there isn’t, but I made 36 of these ‘ED’ hoists in 2008 and sold them all (with no advertising) in 4 years. Time to make some more . . .

Like the thread on the ‘BM’ clam shell bucket, the ‘ED’ hoist has a number of parts that will be broken into individual posts. I’ll quickly go over how I made the parts for the 36 assemblies made in 2008, then how I do them now.

First big change is the steel stock used. Gilbert nickel-plated a lot of their parts from 1913 – 1953. The 2008 batch were made from plain steel and nickel-plated. I have a 2-gallon nickel plating set up from Caswell Plating, but went with a commercial plater at the time because of the sheer volume of parts I had made up. Unfortunately, the plater I used back then is now out of business. So, out of laziness, I went a different route and made all of the nickel-plated parts out of 304 stainless steel in a 2B finish. That finish looks very close to nickel plating. The jury is still out on stainless or plain carbon steel; I’m currently looking at a new commercial plater.

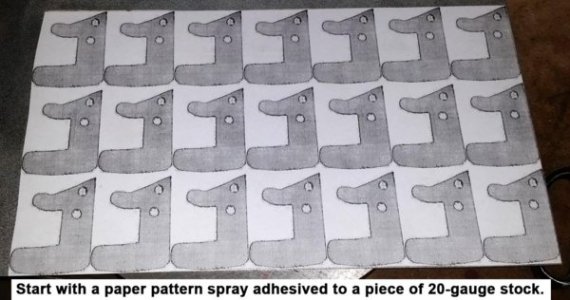

The first part I’ll cover are the main side plates. There are two side plates with 18 holes and 6 slots that are joined by three steel rods. My original repro batch had the side plates done by gluing a paper hole template to the steel blank which were then center punched, and the holes were punched on my Roper Whitney #218 punch press. The paper template also had the trim edge of the side plates which were cut on a shear and with aviator snips.

On to 2017 . . . For the next batch I took advantage of the addition of a DRO on my mill. I measured up an original ‘ED’ side plate and knew the (X, Y) coordinates of all of the holes and the corners of the trimmed edge of the plate. Made a punch template on the mill for the current run. Started by indicating a plate of 3/8” CRS to the mill table, then started spot drilling and drilling holes for the side plate holes. By the way, the holes were roughly 11/64” as Gilbert used 5/32” rod stock for axles. The corners of the trimmed edge were drilled with an 1/8” drill instead of the 11/64”. Plan was to transfer punch those holes, then trim the side plates to size by basically going dot to dot.

I had to make a modified 11/64” punch for my Roper Whitney punch press as the stock punch wasn’t quite long enough to get through the 3/8” steel, 0.036” side plate blank and the die. Simple lathe job here, made up 2 of them so I had a backup.

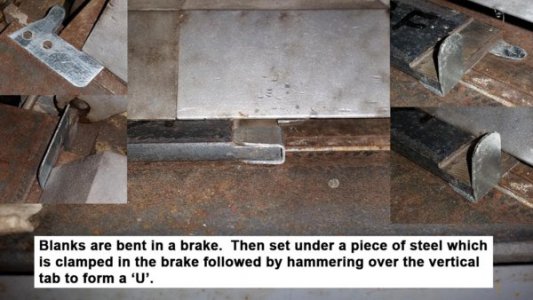

Started the side plates by gluing a template for the foot flange slotted holes. Knocked in the holes with a 0.172” x 0.281” slotted punch. Then folded the flange on my DiAcro brake.

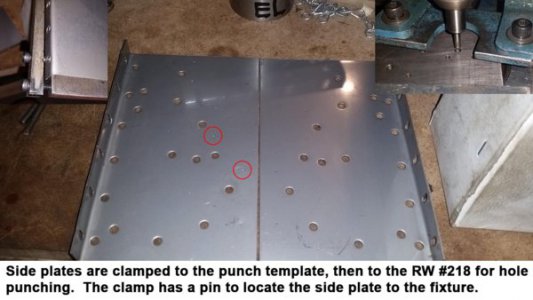

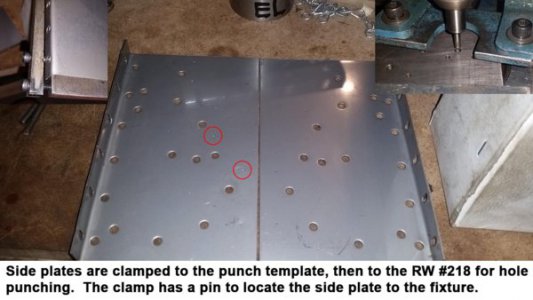

Next, the side plate is clamped to the 3/8” steel punch template. The clamp is a piece of 3/8” bar stock and has a 10-24 cap screw with its end turned to 11/64” to act as a locating pin to hold the side plate in the correct position.

I used an 1/8” transfer punch to mark the corners of the trimmed edge of the plate. Then knocked through the 18 holes with my modified 11/64” punch. The side plates have a LH and RH side which is accomplished by flipping the blank on the 3/8” punch template.

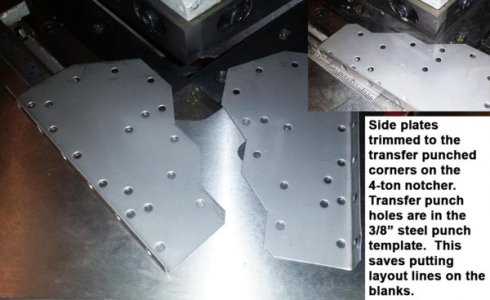

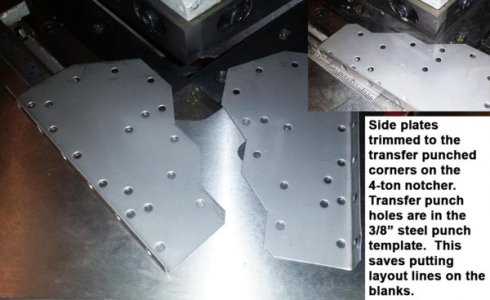

The edges were trimmed to the corners using a 4-ton notcher. The first hit is just off the transfer punched hole so I had something to see while lining up the next cut.

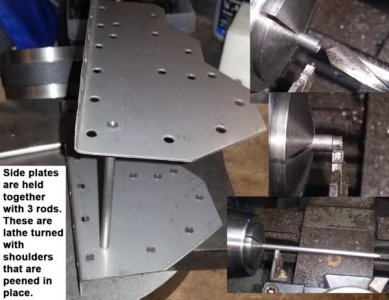

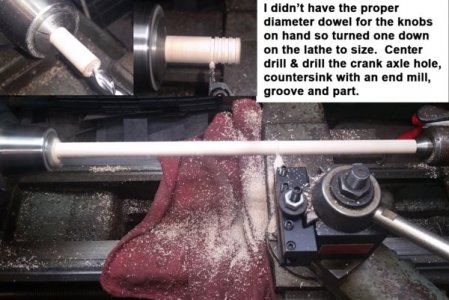

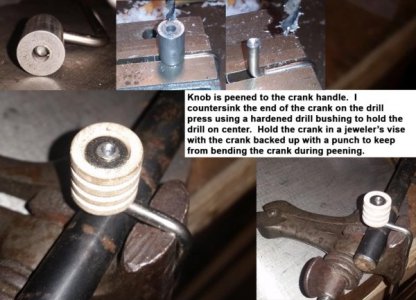

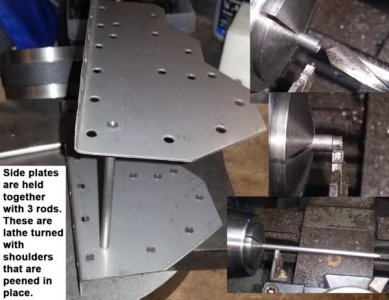

Next are the steel rods that hold the side plates together. These are 3/16” rod stock with a shoulder turned to 11/64” inch. The ends are peened to the side plates to hold them together. I use a spotting drill to countersink a hole at the end of the rods. Makes it much easier to peen over than a piece of solid stock.

Bruce

The lower crank has a ‘P49’ 18-tooth gear on it which engages with a ‘BF’ ratchet. The ratchet edge jams into the 18-tooth gear and allows the crank to only turn in one direction. The child would have to manually release the ratchet by pulling back on a finger catch to turn the drum the opposite direction.

Gilbert illustrated a number of crane models that used the ‘BM’ clam shell bucket and ‘ED’ hoist. The clam shell bucket had a counterweight, which when raised or lowered relative to the bucket itself opened or closed the bucket. Perfect application for the ‘ED’ hoist and the upper two drums. The upper drum was strung to the counterweight and the middle drum to the clam shell itself. The child could slide the upper crank to engage just the upper drum, then turn the crank in either direction to open or close the bucket. Then slide the crank so both drums were engaged, then turn the crank to raise or lower the bucket with the bucket opening staying put. The lower drum was strung to a crane boom. Turning the crank without pulling back on the ratchet raised the boom. The child would grab the lower crank, pull back on the ratchet, and turn the crank to lower the boom.

You’d think that the ‘ED’ being in just two large sets (a very nice 1927 No. 10 set sold at auction for $17,000 in 2006) that there wouldn’t be a lot of demand for it. Well, there isn’t, but I made 36 of these ‘ED’ hoists in 2008 and sold them all (with no advertising) in 4 years. Time to make some more . . .

Like the thread on the ‘BM’ clam shell bucket, the ‘ED’ hoist has a number of parts that will be broken into individual posts. I’ll quickly go over how I made the parts for the 36 assemblies made in 2008, then how I do them now.

First big change is the steel stock used. Gilbert nickel-plated a lot of their parts from 1913 – 1953. The 2008 batch were made from plain steel and nickel-plated. I have a 2-gallon nickel plating set up from Caswell Plating, but went with a commercial plater at the time because of the sheer volume of parts I had made up. Unfortunately, the plater I used back then is now out of business. So, out of laziness, I went a different route and made all of the nickel-plated parts out of 304 stainless steel in a 2B finish. That finish looks very close to nickel plating. The jury is still out on stainless or plain carbon steel; I’m currently looking at a new commercial plater.

The first part I’ll cover are the main side plates. There are two side plates with 18 holes and 6 slots that are joined by three steel rods. My original repro batch had the side plates done by gluing a paper hole template to the steel blank which were then center punched, and the holes were punched on my Roper Whitney #218 punch press. The paper template also had the trim edge of the side plates which were cut on a shear and with aviator snips.

On to 2017 . . . For the next batch I took advantage of the addition of a DRO on my mill. I measured up an original ‘ED’ side plate and knew the (X, Y) coordinates of all of the holes and the corners of the trimmed edge of the plate. Made a punch template on the mill for the current run. Started by indicating a plate of 3/8” CRS to the mill table, then started spot drilling and drilling holes for the side plate holes. By the way, the holes were roughly 11/64” as Gilbert used 5/32” rod stock for axles. The corners of the trimmed edge were drilled with an 1/8” drill instead of the 11/64”. Plan was to transfer punch those holes, then trim the side plates to size by basically going dot to dot.

I had to make a modified 11/64” punch for my Roper Whitney punch press as the stock punch wasn’t quite long enough to get through the 3/8” steel, 0.036” side plate blank and the die. Simple lathe job here, made up 2 of them so I had a backup.

Started the side plates by gluing a template for the foot flange slotted holes. Knocked in the holes with a 0.172” x 0.281” slotted punch. Then folded the flange on my DiAcro brake.

Next, the side plate is clamped to the 3/8” steel punch template. The clamp is a piece of 3/8” bar stock and has a 10-24 cap screw with its end turned to 11/64” to act as a locating pin to hold the side plate in the correct position.

I used an 1/8” transfer punch to mark the corners of the trimmed edge of the plate. Then knocked through the 18 holes with my modified 11/64” punch. The side plates have a LH and RH side which is accomplished by flipping the blank on the 3/8” punch template.

The edges were trimmed to the corners using a 4-ton notcher. The first hit is just off the transfer punched hole so I had something to see while lining up the next cut.

Next are the steel rods that hold the side plates together. These are 3/16” rod stock with a shoulder turned to 11/64” inch. The ends are peened to the side plates to hold them together. I use a spotting drill to countersink a hole at the end of the rods. Makes it much easier to peen over than a piece of solid stock.

Bruce