-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Facets in my 16 TPI Threads - Need some help!

- Thread starter TX COWDOC

- Start date

- Joined

- Sep 8, 2019

- Messages

- 4,392

I'm feeding on the compound at 29.5 degrees. Not sure how well I will do grinding a 60 deg threading tool.

If you have more money than time, you can buy preground tool bits. I use them.

8 pc. Ground HSS Tool Bit Set 3/8"

<h1>H5687 8-Piece 3/8" HSS Tool Bit Set </h1> <p>Usually used on metal lathes, the H5687 tool bits can also be ground down and used for engraving metal. <p>This set comes with these sharpened profiles: offset right and left-hand tools with chip breaker, straight and ship breaker style treading...

Also, Accusize sells the same. Much less expensive on Amazon:

Last edited:

Thank you - I may just try the HSS to rule out bit material.If you have more money than time, you can buy preground tool bits. I use them.

8 pc. Ground HSS Tool Bit Set 3/8"

<h1>H5687 8-Piece 3/8" HSS Tool Bit Set </h1> <p>Usually used on metal lathes, the H5687 tool bits can also be ground down and used for engraving metal. <p>This set comes with these sharpened profiles: offset right and left-hand tools with chip breaker, straight and ship breaker style treading...www.grizzly.com

Also, Accusize sells the same.

- Joined

- Sep 8, 2019

- Messages

- 4,392

Thank you - I may just try the HSS to rule out bit material.

I must like these because I just bought more of the 1/2” Accusize pre-ground HSS tool bits.

Last edited:

Another vote for HSS. It really isn't very hard to grind. On bits that can be set very close to the tool holder, I use smaller blanks to save grinding effort. My tool holders will take 5/8" bits but my threading tool is just 3/8" and works fine. I thread at the highest speed that I feel comfortable with. I can do that because I thread away from the chuck. I don't fumble around moving both the compound and the cross slide. Unless you are cutting some huge threads or maybe Acme there is very little force on the lathe or the tool so letting the tool cut on both sides is no big deal. Eliminate compound issues by keeping it pulled back, no overhang and locked. I didn't develop this method. It's a Joe Pie thing. It works!

OK, now it's the turn of all those who are opposed.

OK, now it's the turn of all those who are opposed.

- Joined

- May 10, 2017

- Messages

- 1,199

Hey neighborI'm feeding on the compound at 29.5 degrees. Not sure how well I will do grinding a 60 deg threading tool.

PM me an address and I’ll send you a 60* HSS tool to try

- Joined

- Dec 20, 2012

- Messages

- 9,422

Also, Accusize sells the same. Much less expensive on Amazon:

Wow, better read the reviews on those Accusize tool bits ... maybe better to grind your own?

- Joined

- Dec 26, 2015

- Messages

- 2,079

If you need to use HSS because of limited feed/speed rates, but would prefer to use indexable tools instead of solid shank HSS, this kit from A.R Warner is ideal. The HSS On-Edge (vertical V-shape) inserts are available in neutral and positive rake. I love this kit for threading softer materials.

Last edited:

- Joined

- Mar 25, 2013

- Messages

- 4,617

This works much better if you use beer. Especially something dark and hoppy...I'll check the glass of water / harmonics. Thanks for all of the info.

David- what is the point of the insert holder being tilted and counteracting the angle of the insert? Is this purely for clearance? This tool is labeled as an external threading tool by the manufacturer so clearance would not be an issue?

Robert

- Joined

- Jan 28, 2011

- Messages

- 3,485

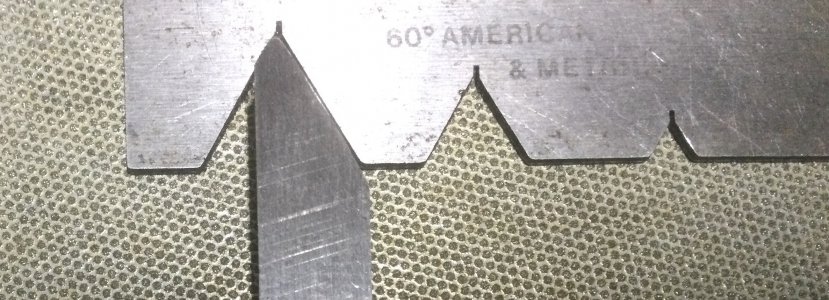

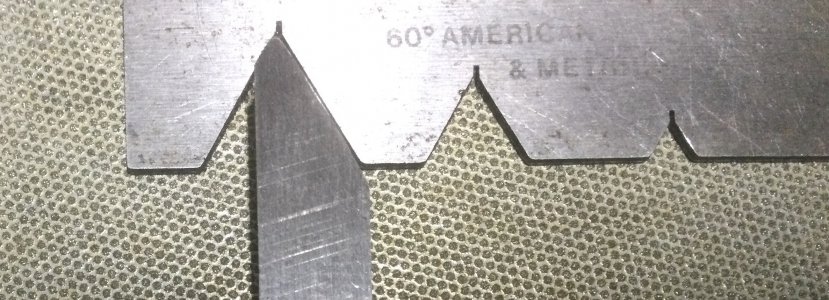

I use HSS at home, cheaper and regrind to what I need. Also for threading I only sharpen one side on one of my tools. With the correct 30 degree offset I get a 60 degree cut. Easier to grind!

The other tool which I use in my boring bar for internal threads is ground on 2 sides but you can see in the photo that one is with a long edge while the other is very short. The cutting edge is the long side. This tool is upside down to the way it is mounted in the bar.

Pierre

The other tool which I use in my boring bar for internal threads is ground on 2 sides but you can see in the photo that one is with a long edge while the other is very short. The cutting edge is the long side. This tool is upside down to the way it is mounted in the bar.

Pierre