- Joined

- Oct 7, 2020

- Messages

- 2,117

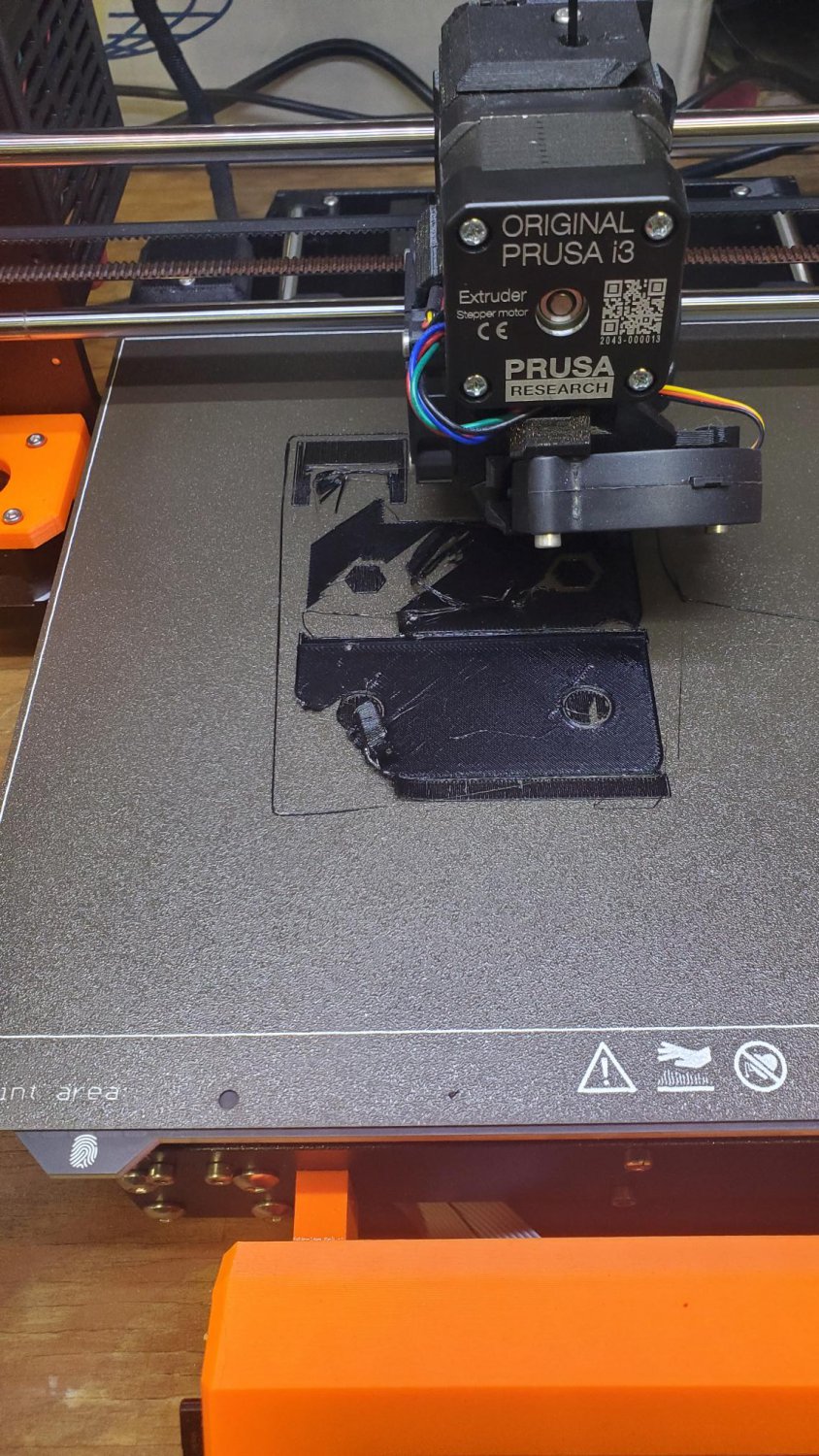

So, I had a hard time getting this to work after maybe the fourth failed start, I used the glue stick and it worked. I could not get the Aquanette that has been recommended, I tried another brand it didn't work.

The little welding cart for my MIG welder has the handle at 24" high, a little too low for me. I had this old Weed eater handle just laying around. I think it is going to work just fine.

The little welding cart for my MIG welder has the handle at 24" high, a little too low for me. I had this old Weed eater handle just laying around. I think it is going to work just fine.