- Joined

- Jul 5, 2014

- Messages

- 2,772

I have a holley sniper stand alone fuel injection unit on my 55 chevy. It's already been installed and on first startup it leaked so bad it covered my intake manifold. So Holley made me a deal to upgrade to a newer unit. I will be approximately mid next month for it to arrive.

After I had the problem with the fuel leak I joined a couple of forums and read up on the sniper injection and found people have a lot of problems with them, mostly of their own doing from wiring and other things. I did read one knowledgeable person on what he did to prevent problems. One thing he said he used is ferrite rings. He didn't elaborate on how he used them and I did a some research but I feel I'll get a much better education from members on here about their use.

So there is a main power wire (10awg) to my battery (in the trunk) , a ground, fuel pump feed, 02 sensor, coolant temp sensor, and a 12v ignition hot wire to turn the unit on. Presently there is a separate wire to the battery to a relay that gives clean power to the unit and switch it on by the ignition to isolate the "dirty" power from the unit.

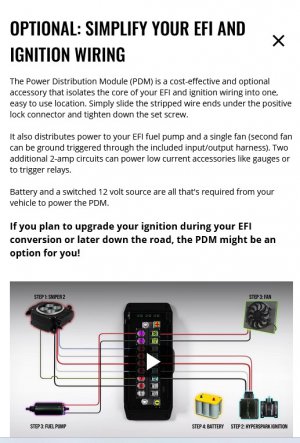

With the new sniper2 unit there is a power distribution box I bought. Here is info on that. FYI: I wil not be using the unit to control my cooling fans.

After I had the problem with the fuel leak I joined a couple of forums and read up on the sniper injection and found people have a lot of problems with them, mostly of their own doing from wiring and other things. I did read one knowledgeable person on what he did to prevent problems. One thing he said he used is ferrite rings. He didn't elaborate on how he used them and I did a some research but I feel I'll get a much better education from members on here about their use.

So there is a main power wire (10awg) to my battery (in the trunk) , a ground, fuel pump feed, 02 sensor, coolant temp sensor, and a 12v ignition hot wire to turn the unit on. Presently there is a separate wire to the battery to a relay that gives clean power to the unit and switch it on by the ignition to isolate the "dirty" power from the unit.

With the new sniper2 unit there is a power distribution box I bought. Here is info on that. FYI: I wil not be using the unit to control my cooling fans.