- Joined

- Feb 1, 2015

- Messages

- 9,646

I had a bucket of old files that had been sitting my barn for the past thirty years. As I recall, they were purchased at an auction of a blacksmith shop. They were well used at the time and had accumulated a generous coating of rust after a more than a quarter century of exposure to the elements and nesting birds.

Last week, I decided to take a shot at restoring them. I started by cleaning off the loose crud and soaking them in EvapoRust for a couple of days. That wasn't proceeding too well so I switched to electrolysis. With the bulk of the rust removed, I wire brushed them ri remove any remaining. It is important to remove as much of any loading of the file teeth as possible for the sharpening process to work well.

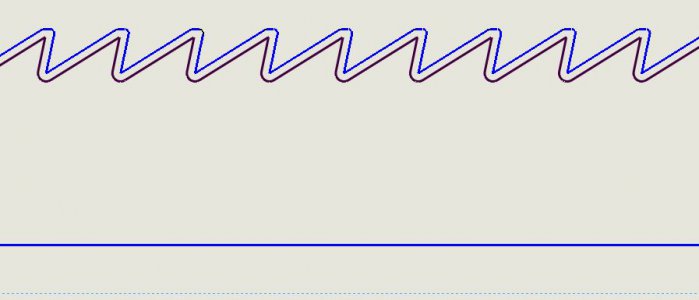

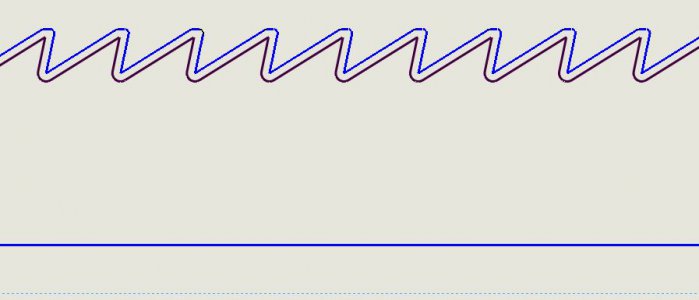

The sharpening process consists of soaking in muriatic acid (HCl) which etches the surface of the steel. When acid etches a metal surface, it removes metal at a fairly constant rate regardless of contour. As a result, a etching a rounded feature will effectively reduce the radius and if carried long enough the radius becomes zero, resulting in a sharp edge. The following illustration shows a section of a worn file (blue) and the result of the etching process (black).

For etching purposes, I made a container from 1-1/2" PVC pipe and an end cap. This minimizes the volume of acid required. I used full strength acid (22%) which gives off obnoxious fumes so this is definitely a task to be done outdoors. Etching time depends upon the condition of the file and on the size of the teeth. Well worn files and/or larger teeth require more time.

The files can be removed from time to time to check their condition. To check, I rinse it in tap water, dry, and file a test piece of 1018. I am looking for a good bite with light to moderate filing pressure. If the file is sharp, I soak it in washing soda or baking soda solution to neutralize any residual acid, rinse with water, and dry thoroughly. At that point, the file is ready to use.

I ran 33 files through the etching process. One file was too far gone to restore it. This was partially due to loading of the file teeth acting as a resist which essentially just etches the tops of the teeth, hence the necessity of cleaning any loading of the teeth before etching. These files are all old American steel with the exception of a couple of German and Swiss files. With new files running $6 and up and commercial resharpening running around $3 per file, this was a fairly lucrative project.

Last week, I decided to take a shot at restoring them. I started by cleaning off the loose crud and soaking them in EvapoRust for a couple of days. That wasn't proceeding too well so I switched to electrolysis. With the bulk of the rust removed, I wire brushed them ri remove any remaining. It is important to remove as much of any loading of the file teeth as possible for the sharpening process to work well.

The sharpening process consists of soaking in muriatic acid (HCl) which etches the surface of the steel. When acid etches a metal surface, it removes metal at a fairly constant rate regardless of contour. As a result, a etching a rounded feature will effectively reduce the radius and if carried long enough the radius becomes zero, resulting in a sharp edge. The following illustration shows a section of a worn file (blue) and the result of the etching process (black).

For etching purposes, I made a container from 1-1/2" PVC pipe and an end cap. This minimizes the volume of acid required. I used full strength acid (22%) which gives off obnoxious fumes so this is definitely a task to be done outdoors. Etching time depends upon the condition of the file and on the size of the teeth. Well worn files and/or larger teeth require more time.

The files can be removed from time to time to check their condition. To check, I rinse it in tap water, dry, and file a test piece of 1018. I am looking for a good bite with light to moderate filing pressure. If the file is sharp, I soak it in washing soda or baking soda solution to neutralize any residual acid, rinse with water, and dry thoroughly. At that point, the file is ready to use.

I ran 33 files through the etching process. One file was too far gone to restore it. This was partially due to loading of the file teeth acting as a resist which essentially just etches the tops of the teeth, hence the necessity of cleaning any loading of the teeth before etching. These files are all old American steel with the exception of a couple of German and Swiss files. With new files running $6 and up and commercial resharpening running around $3 per file, this was a fairly lucrative project.