B

bvd1940

Forum Guest

Register Today

Well I got the furnace filled with fire brick and home made refractory (Im sure messy):biggrin: It has been drying for about a month and have started on the burner and will post pics for those that are interested. The furnace body is a old water pressure tank scrounged from the well driller.

Well I got the furnace filled with fire brick and home made refractory (Im sure messy):biggrin: It has been drying for about a month and have started on the burner and will post pics for those that are interested. The furnace body is a old water pressure tank scrounged from the well driller. I am building a Oliver-upwind propane burner from BackyardMetalcasting.com which looks like the simplest to build and operate with the least problems.

I should have taken more pics as I went but was not planning on posting this to the board, did not know if anyone would be interested :thinking:

Well my hand to hand combat trying to upload pics I give up:banghead: I managed to get one pic loaded and found thats all I could upload so I quit:banghead:

http://www.hobby-machinist.com/attachment.php?attachmentid=29380&d=1320811103&thumb=1&stc=1

I think I got one uploaded:biggrin:

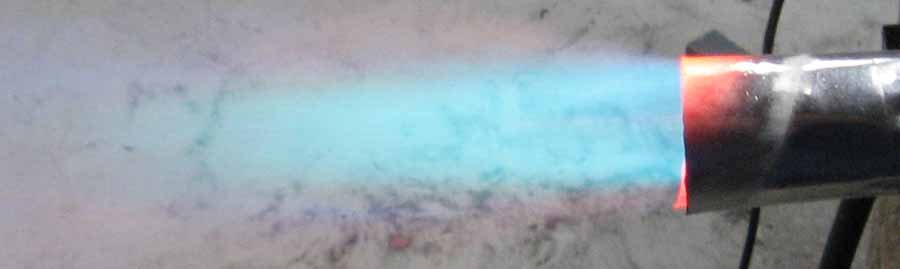

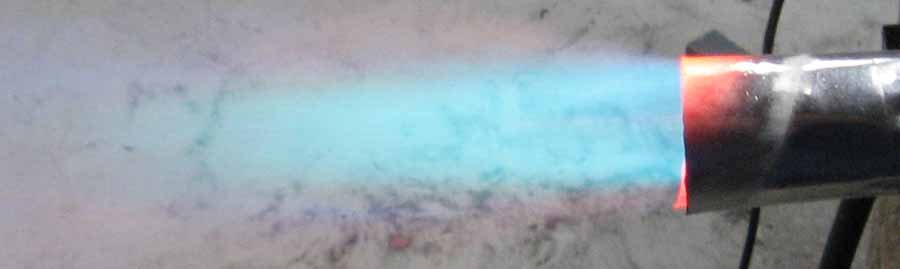

Well I got the burner up and running

How bout that it worked

Well back to the furnace as I have to build a lift for the lid and test fire it:thumbzup:

Monday gota go to the Doctor Monday the get my preop meeting taken care of & find out when he whacks on me. Nothing serious but wont be able to lift more than 10 lbs after he gets done for at least 6 weeks:angry: so I will be putz in mode for 6 weeks:nono:

Last edited by a moderator: