- Joined

- Mar 17, 2024

- Messages

- 43

I am working on restoring a particularly trashed FIE E15 revolver and one of the parts that I can't buy is the firing pin. I don't have a lathe but I made a functional replacement using a drill press and file out of 12L14 steel as a test. Now I feel confident I can make the part so I want to get a better steel for the purpose.

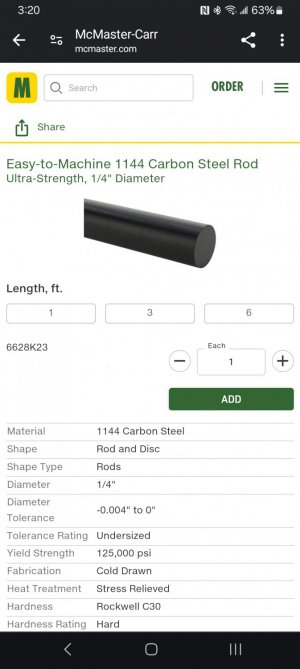

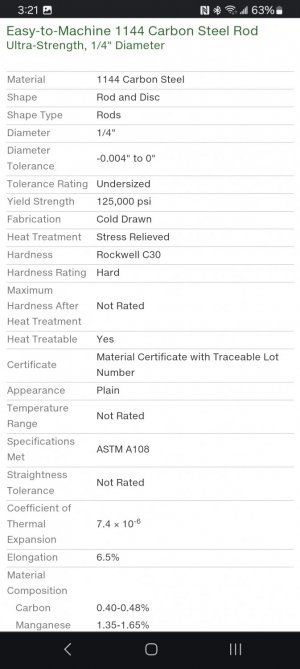

I ordered some 1144 rod from McMasters and I was wondering if it would be a good choice or is there something better available.

I am extremely limited in heat treating ability as all I have is propane and oxyacetylene torches and my wife's oven.

I ordered some 1144 rod from McMasters and I was wondering if it would be a good choice or is there something better available.

I am extremely limited in heat treating ability as all I have is propane and oxyacetylene torches and my wife's oven.