- Joined

- Mar 10, 2012

- Messages

- 125

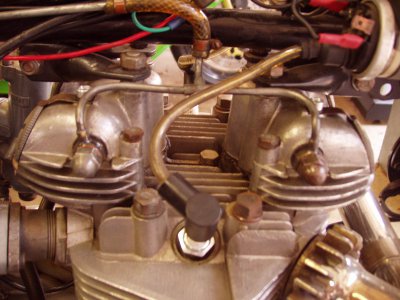

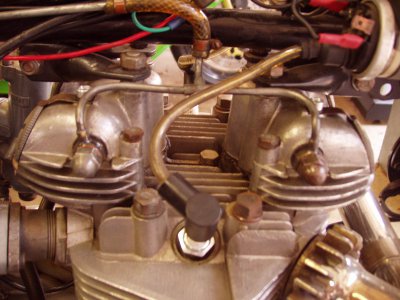

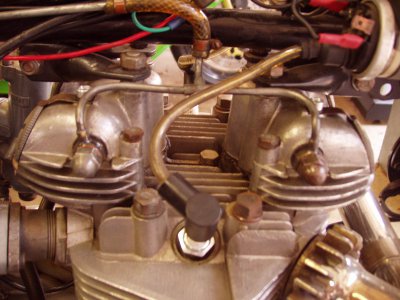

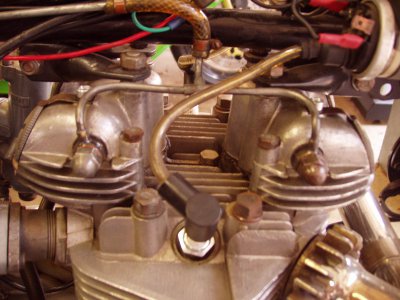

When I first started riding motorcycles in the late 60's, I always admired a custom (of sorts) Triumph stored in a room adjacent to one of our local dealerships. The son of the owner had taken on a project that involved turning and replacing all the cadium plated bolts with stainless steel ones. When my father gave me custody of his 1970 Bonneville a few years back, I decided to do the same as a part of the "freshening up" I planned for his well preserved favorite. While two or three suppliers advertised stainless cylinder studs and head bolts, all of them were "out of stock" once I had the heads and cylinders off the bike. I did what any sane person would do: bought a lathe and made my own (after about a year of reading and experimenting). I found that each project led to another, and another, and another. The original bolts were pretty well rusted up, so I turned and threaded four studs and for head bolts. Only three of each are shown here as I stopped to complete another project for my dad (an antique gun oiler grouped with the bolts below).

Next, I replaced the hexagonal engine mounting stud nut, the rear brake rod, brake adjuster, and stoplight actuator rod with stainless parts.

Then we needed a triple clamp bolt and acorn nut. Then we needed chain adjusters which precipitated the need for a rotary table and mill/drill (covered in another post about 6 months ago). The Bonny seems to be a perpetual project in progress, as does the need for additional machinery (the mill/drill's z axis limitations absolutely forced me to acquire a used Bridgeport ) ).

) ).

The more I learn to do, the more amazed I am at how much more there is to learn (mostly, now, from the folks on this list. Thanks!).

Next, I replaced the hexagonal engine mounting stud nut, the rear brake rod, brake adjuster, and stoplight actuator rod with stainless parts.

Then we needed a triple clamp bolt and acorn nut. Then we needed chain adjusters which precipitated the need for a rotary table and mill/drill (covered in another post about 6 months ago). The Bonny seems to be a perpetual project in progress, as does the need for additional machinery (the mill/drill's z axis limitations absolutely forced me to acquire a used Bridgeport

The more I learn to do, the more amazed I am at how much more there is to learn (mostly, now, from the folks on this list. Thanks!).