- Joined

- Feb 5, 2018

- Messages

- 637

I wanted to start a thread about my first scraping project.

I got the idea a couple months ago after reading about hand scraping and thinking about the cross slide on my lathe. It definitely has a little wear and gets tight near the endof its travel. Well there is only one way to fix it correctly, scrape it back into proper alignment.

After doing a lot of reading and checking out tools, i started ordering supplies.

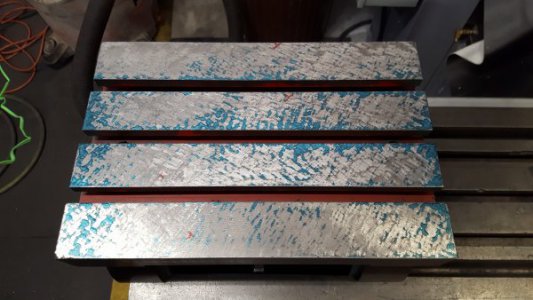

I bought the die spotting ink that is recommended by people on the other board. The big decision was finding a granite surface plate at a reasonable price. I ended up getting a 12"×18". It was pretty cheap and the next size up was quite a bit more. It didn't take long to figure out it needs to be bigger. Oh well ya gotta start somewhere.

I bought a Sandvik scraper and found another carbide insert so I could grind the common radius needed.

The grinder and lap was something I thought about for awhile. I had a variable speed motor off a wood lathe sitting on the shelf that will work ok. I turned an arbor to hold a diamond lapping disk from e bay. It works ok but has a lot of runout.

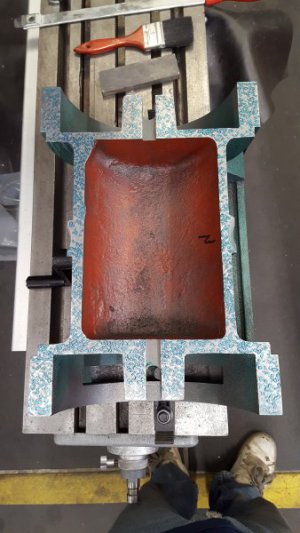

I bought a rough casting for a straight edge from Gary Martin. They are priced good for a first time peoject.

I milled it flat and started scraping.

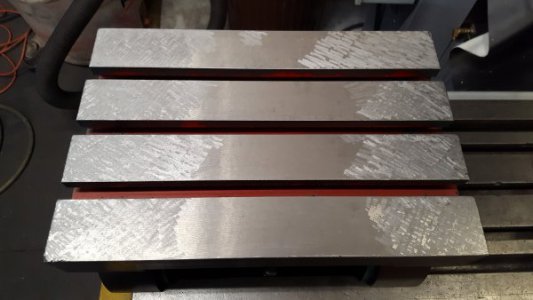

It didn't take long to realize it is more difficult than it looks. I started before I had a very fine wheel to lap the insert with. You can see it in the finish of the scrape marks.

Here are some pics of the straight edge as I was working on it.

Joe Hynes

I got the idea a couple months ago after reading about hand scraping and thinking about the cross slide on my lathe. It definitely has a little wear and gets tight near the endof its travel. Well there is only one way to fix it correctly, scrape it back into proper alignment.

After doing a lot of reading and checking out tools, i started ordering supplies.

I bought the die spotting ink that is recommended by people on the other board. The big decision was finding a granite surface plate at a reasonable price. I ended up getting a 12"×18". It was pretty cheap and the next size up was quite a bit more. It didn't take long to figure out it needs to be bigger. Oh well ya gotta start somewhere.

I bought a Sandvik scraper and found another carbide insert so I could grind the common radius needed.

The grinder and lap was something I thought about for awhile. I had a variable speed motor off a wood lathe sitting on the shelf that will work ok. I turned an arbor to hold a diamond lapping disk from e bay. It works ok but has a lot of runout.

I bought a rough casting for a straight edge from Gary Martin. They are priced good for a first time peoject.

I milled it flat and started scraping.

It didn't take long to realize it is more difficult than it looks. I started before I had a very fine wheel to lap the insert with. You can see it in the finish of the scrape marks.

Here are some pics of the straight edge as I was working on it.

Joe Hynes