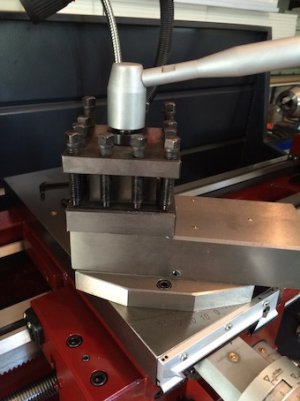

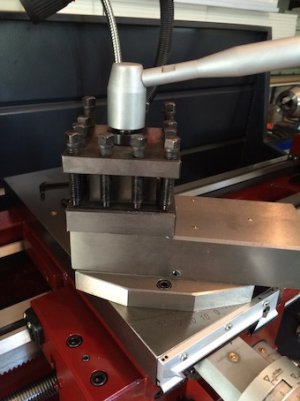

My new Sieg Runmaster 13 x 40 lathe has a rotating 4way toolpost as standard (Pic 1). I wish to mount a new QCTP which requires a straight 16mm shaft.

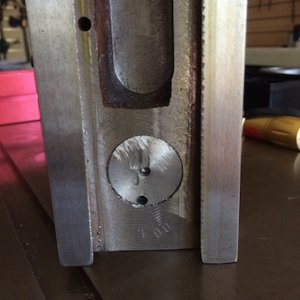

Unfortunately the post on which the supplied TP is mounted has a 25mm boss at the bottom of the 16mm threaded section (Pic2) which will have to be machined away down to the top of the topslide.

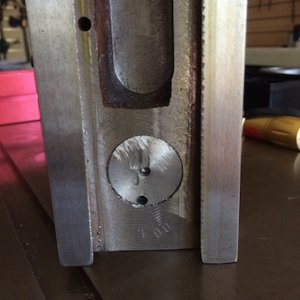

Underneath the topslide there is further enlarged boss to stop the toolpost pulling through with a locating roll pin to stop the post rotating when tightening the locking nut (Pic3).

I need to remove the post for machining. I have drilled out the roll pin but can't easily decide whether the post is a threaded insert or an interference friction fit. That is do I have to unscrew the post or press it out on a press? From the marks on the underside I am pretty sure it is a press fit but I don't want to chance breaking the topslide if it is threaded!

I am sure I have seen a similar toolpost Q somewhere on the Web but a search has failed to find it.

Has any body seen a similar set up and can offer advice?

Unfortunately the post on which the supplied TP is mounted has a 25mm boss at the bottom of the 16mm threaded section (Pic2) which will have to be machined away down to the top of the topslide.

Underneath the topslide there is further enlarged boss to stop the toolpost pulling through with a locating roll pin to stop the post rotating when tightening the locking nut (Pic3).

I need to remove the post for machining. I have drilled out the roll pin but can't easily decide whether the post is a threaded insert or an interference friction fit. That is do I have to unscrew the post or press it out on a press? From the marks on the underside I am pretty sure it is a press fit but I don't want to chance breaking the topslide if it is threaded!

I am sure I have seen a similar toolpost Q somewhere on the Web but a search has failed to find it.

Has any body seen a similar set up and can offer advice?