- Joined

- Feb 27, 2014

- Messages

- 2,130

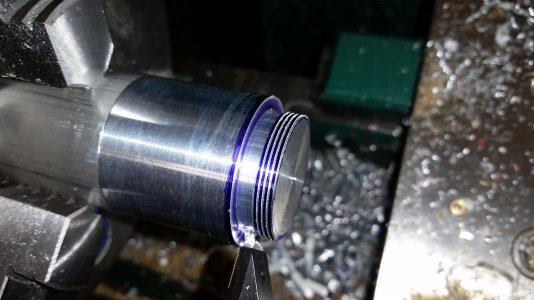

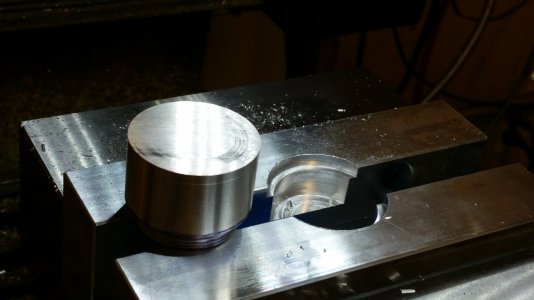

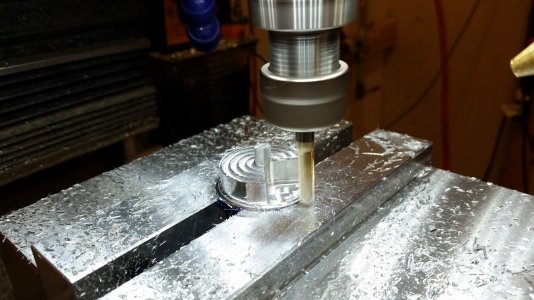

I am in the process of making a unique flashlight. What will make this flashlight different is that it will be convertible to a lighted Kite stake. In in the kite stake mode, you will be able to screw an 8" pointed state (1/4" drill rod) onto the bottom to allow it to be stuck into the ground and on the top the lens will be replaced with a top that will redirect the light out the sides so it can be see on a dark field.

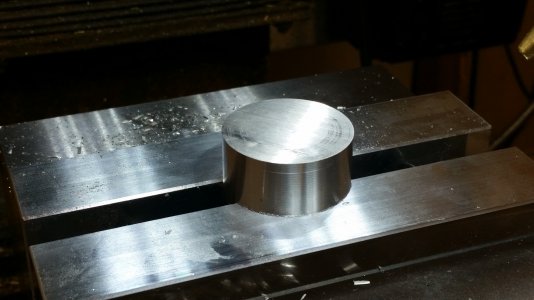

This project is going to challenge my skills to the max. I have a few tools now and have been building up to this point. I plan to make the flashlight mostly out of 6061 aluminum but I am using 360 Brass for one part of the on/off switch.

I have made a proof of concept on/off switch that while not fully functional was good enough to convince me to that it will work. I am going to build 6 at the same time so if I destroy any parts in the process I hopefully will still have a few when I finish.

Don't expect this to move along quickly. I expect this will take me many months or even over a year to complete as I have many obligations on my time and interests.

This project is going to challenge my skills to the max. I have a few tools now and have been building up to this point. I plan to make the flashlight mostly out of 6061 aluminum but I am using 360 Brass for one part of the on/off switch.

I have made a proof of concept on/off switch that while not fully functional was good enough to convince me to that it will work. I am going to build 6 at the same time so if I destroy any parts in the process I hopefully will still have a few when I finish.

Don't expect this to move along quickly. I expect this will take me many months or even over a year to complete as I have many obligations on my time and interests.