-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flat Head Hit Miss Engine

- Thread starter rogerl

- Start date

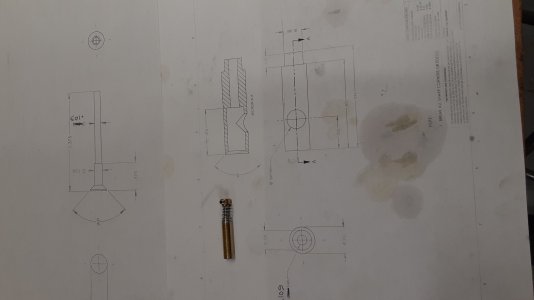

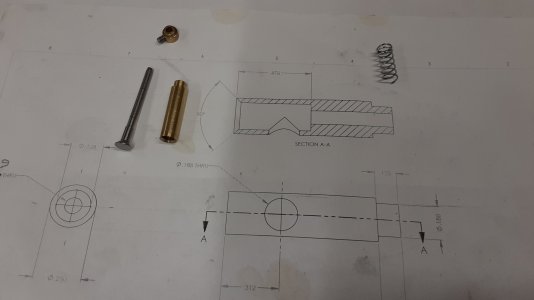

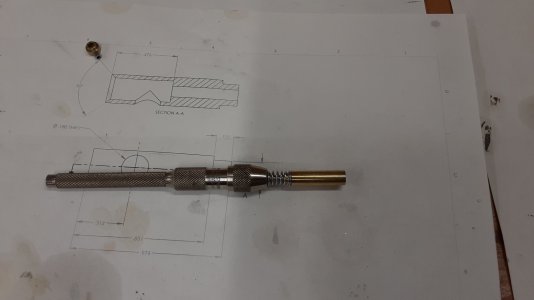

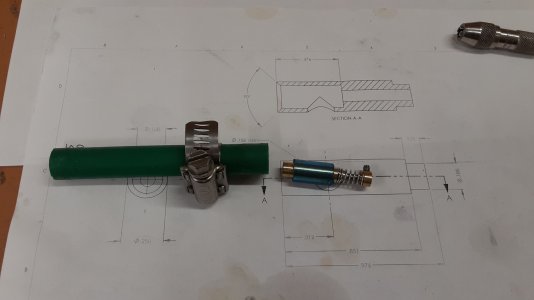

Below are some photos of the design and the test rig. The outer body of the brass is .250". The hole drilled in the brass is .187. The hole for the stem is .109. The valve OD is .250 with a .125 step to the .109 diameter. I used a 90 degree countersink to cut the taper in the brass and a tool bit ground at 45 degrees and aligned to the chuck with a 45 degree block to cut the angle on the valve. I used a Starrett pin vice to grab the end of the valve to lap it in. To test it I put a piece of polyurethane tubing, 1/4" ID 3/8" OD, over the valve body then a piece of 1/2" OD 3/8" ID polyurethane tubing over that and secured it with a breeze clamp. I then hooked it to my regulator set at 40 psi. The bubbles in the photo were taken at 20 psi. At 40 psi it is a constant stream of air coming out around the stem.

I was using a lapping compound made from 220 grit carbide powder and oil, than 600 grit carbide powder and oil, then the Tormek polishing compound. Under the microscope there were lots of scored lines on the steel and the brass. I tried re-cutting the brass and polishing the steel then using just the Tormek polishing compound and that did no better. What am I doing wrong?

Roger L

I was using a lapping compound made from 220 grit carbide powder and oil, than 600 grit carbide powder and oil, then the Tormek polishing compound. Under the microscope there were lots of scored lines on the steel and the brass. I tried re-cutting the brass and polishing the steel then using just the Tormek polishing compound and that did no better. What am I doing wrong?

Roger L

Attachments

- Joined

- Feb 2, 2014

- Messages

- 1,068

I don't think you are doing anything wrong but I am concerned that the hose may be leaking around the clamp and giving a false reading. I would take this setup and hold it in a pail of water up to the regulator to see just where the leaks are. You can then see how much is coming out around the valve stem which is the only place we are concerned with right now.

It doesn't have to be a perfect seal.

Ray

It doesn't have to be a perfect seal.

Ray

The picture on the far right shows the bubbles coming out around the stem. There are some fine bubbles where the tube is connected to the brass but the majority of the bubbles are at the stem. What pressure should I be using? The pressure in the picture was set at 20 psi. I would think I would need to go higher than 20 psi.

Roger L

Roger L

- Joined

- Feb 2, 2014

- Messages

- 1,068

Without seeing it in person I can't tell you if the valve is seating well enough or not. In my experience if I could take a picture of an air bubble before it burst then the valve is fairly well sealed. I don't think I have ever gotten a dry valve to seal completely. When the engine is running there is fuel and oil that helps seal up the valves. Put a few drops of oil in the air pipe and see what happens.

Now saying all that this is your engine and you must make the decision yourself. I don't see anything you are doing wrong or have any suggestion for you to do better.

Air pressure 20, 40, or higher is fine.

Ray

Now saying all that this is your engine and you must make the decision yourself. I don't see anything you are doing wrong or have any suggestion for you to do better.

Air pressure 20, 40, or higher is fine.

Ray