-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flat Head Hit Miss Engine

- Thread starter rogerl

- Start date

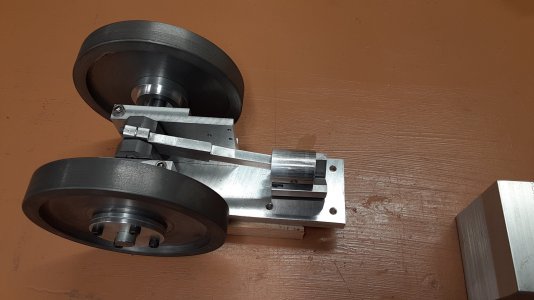

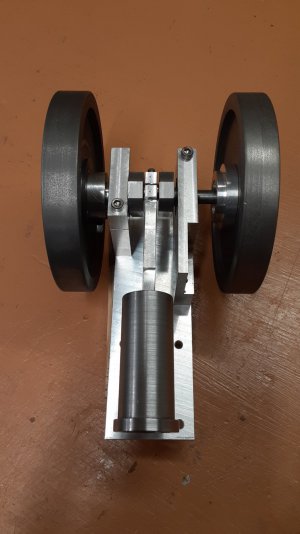

Attached are some photos of the progress. The fly wheels are made from 3 pound cast iron weights. I really hate machining cast iron. I bought the weights from a local metal recycling company. The crank shaft is made from pieces. I am waiting to put the O ring groove in the piston until I get the O rings. I have the block of aluminum for the cylinder housing. I need to finish the drawing then start machining. The cylinder liner is 1020 steel. I was able to polish the bore to get it nice and smooth. It is coming along.

Roger L

Roger L

Attachments

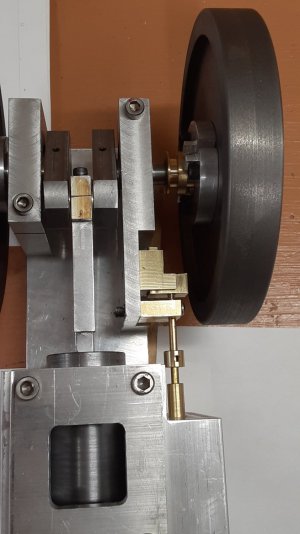

I have been making some progress on the engine. I have the cylinder block done, the head done, the valves done, and some of the hit miss parts. I still need to lap in the valves. I am going to make a rig to test the valves before I push the housings into the cylinder block. It will be very difficult to try to lap them in the cylinder block. Most of my spare time has been working with my Science Olympiad teams getting ready for our regional Tournament on March 9th.

Roger L

Roger L

Attachments

- Joined

- Mar 8, 2015

- Messages

- 309

If you are using an O-ring for the piston seal, I have found an aluminum liner works just fine,

I am struggling with the valves. The first set I made I could not get them to seal. I built another set today and the first one I lapped and tested leaked worse than the first ones did. I will look at them with a fresh set of eyes and fingers tomorrow evening.

Roger L

Roger L

Still working on the valves. I can not get the valve to seal. If I look at the two seats under a microscope the surfaces look like the face of a record with a bunch of circular grooves. I started out with 320 grit lapping compound. Is that too coarse? Ray, what lapping compound do you use? I would expect to see a nice flat smooth polished surface, not a bunch of grooves.

Roger L

Roger L

- Joined

- Mar 8, 2015

- Messages

- 309

I use automotive polishing compound. I think Ray uses copper polish. Valve grinding compound is definitely too coarse for the final finishing.

Last edited: