- Joined

- Mar 26, 2018

- Messages

- 8,434

All I have is a small 1/4” shank import fly cutter.

I’ve seen the finish that can be achieved by a properly made tool.

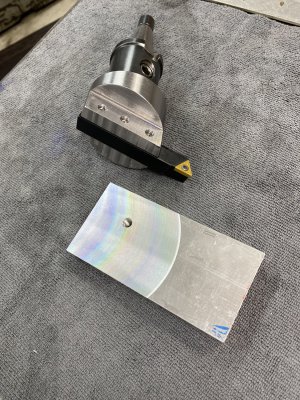

I finished this today. It works beautifully!

This is a 5/8” shank insert holder. This appealed to me for two reasons.

Changing an insert is quick, cheap and easy. I also wanted some stability for this size of cutter.

If you haven’t made one, put it on your to do list.

I’ve seen the finish that can be achieved by a properly made tool.

I finished this today. It works beautifully!

This is a 5/8” shank insert holder. This appealed to me for two reasons.

Changing an insert is quick, cheap and easy. I also wanted some stability for this size of cutter.

If you haven’t made one, put it on your to do list.

Attachments

-

B4A400C0-3DB3-47B4-AD60-477B99388A97.jpeg604 KB · Views: 63

B4A400C0-3DB3-47B4-AD60-477B99388A97.jpeg604 KB · Views: 63 -

B4694F1E-BC27-4182-ACA8-D3BBDE864684.jpeg321.9 KB · Views: 63

B4694F1E-BC27-4182-ACA8-D3BBDE864684.jpeg321.9 KB · Views: 63 -

55BFA901-22A5-4627-8ABE-C5157F4DBED0.jpeg229.4 KB · Views: 55

55BFA901-22A5-4627-8ABE-C5157F4DBED0.jpeg229.4 KB · Views: 55 -

94DD382F-F1BB-4400-A959-020DBA2C45D1.jpeg305.8 KB · Views: 53

94DD382F-F1BB-4400-A959-020DBA2C45D1.jpeg305.8 KB · Views: 53 -

4505D31A-0895-4526-A2EF-FE56270FE8A4.jpeg341 KB · Views: 53

4505D31A-0895-4526-A2EF-FE56270FE8A4.jpeg341 KB · Views: 53 -

B113C645-6BBA-44B2-8598-70C624C93A96.jpeg267.7 KB · Views: 54

B113C645-6BBA-44B2-8598-70C624C93A96.jpeg267.7 KB · Views: 54 -

1C3296AC-39D1-484A-A8AE-70648E3437D9.jpeg303.3 KB · Views: 53

1C3296AC-39D1-484A-A8AE-70648E3437D9.jpeg303.3 KB · Views: 53 -

2AFC70FF-295C-43E7-B103-9ADF8AD87700.jpeg252.6 KB · Views: 53

2AFC70FF-295C-43E7-B103-9ADF8AD87700.jpeg252.6 KB · Views: 53 -

8A9F1E55-D4FB-4240-8D73-AFF55A5DF534.jpeg299.5 KB · Views: 56

8A9F1E55-D4FB-4240-8D73-AFF55A5DF534.jpeg299.5 KB · Views: 56 -

EE308889-B40B-470C-857C-098D5EBCCF4E.jpeg396.9 KB · Views: 64

EE308889-B40B-470C-857C-098D5EBCCF4E.jpeg396.9 KB · Views: 64

![20220910_113650[1].jpg 20220910_113650[1].jpg](https://www.hobby-machinist.com/data/attachments/377/377326-8c72b3a39b4e4f843c066915c685d567.jpg)