- Joined

- May 27, 2016

- Messages

- 3,469

I have been using FreeCAD (because it's free)!

I know that one can get into using Fusion360, but I didn't go there because my PC system is not Microsoft Windows. FreeCAD runs on all platforms (Windows, MacOS, Linux). I have been used to using various kinds of CAD for Electromagnetic Simulation, which are not directly for mechanical modeling, but do, of course, have physical metal shapes in their structures. I had a little play with SolidWorks, but I never got to go the whole learning curve with it, because retirement happily intervened.

For my needs, it's only simple models, and I use the TechDraw workbench to print out some dimensioned views to get grubby in the shop. Of course, FreeCAD kept evolving, all down to a genius crowd contributing faster than the main issue could keep up. Every kind of feature they love, if it's not there, they code it and post it. The best of these get incorporated into the main download, so the third-party tools, while they still can work, become obselete.

So now ..

Just how good do you want it to get?

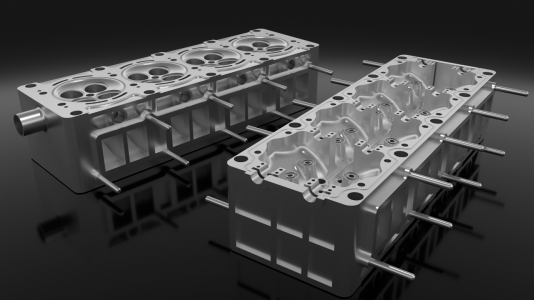

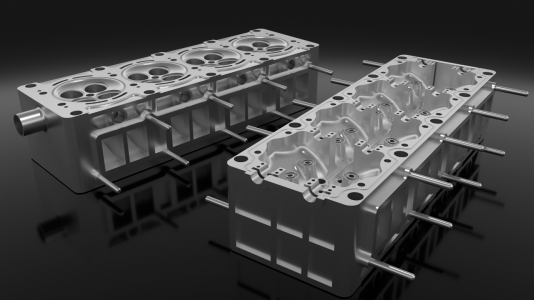

The whole file is freely downloadable from GrabCad.

The step-by-step video is --> HERE

The chap who posts it is from Joko Engineering.

The tricks he gets up to to make sketches become great stuff with simple moves was, for me, a big shift in perspective.

So easy, not many clicks, - and he ends up with a great part

--> HERE

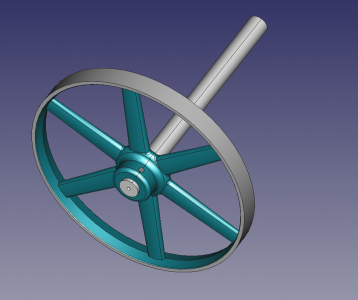

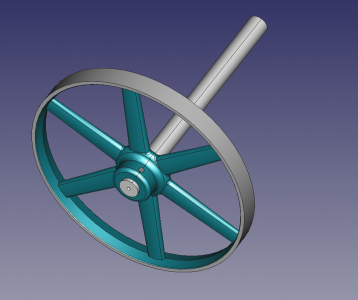

My attempt only needs two countershaft journals (floating about in space) and a correctly located mounting surface to help with the design of a motor adapter bracket. It needs a circular cut-out on a right-angle to mount my replacement motor (ex servomotor with full speed control). I decided to model the drive shaft and wheel, and a pulley of sorts (not seen yet) to help.

My FreeCAD model or the South Bend 9C Underneath drive Countershaft & Drive Wheel.

The real wheel is here (for comparison.

The Joko guy has done another (turbine rotor I think), where he does it side-by-side with SolidWorks, explaining the differences in actions and features.

Clearly now, this free, open source program has gone far beyond the critical point where it takes on a life of it's own. No matter what the field! I can see architecture, mechanical engineering, aeronautical airfoil design, robotics, finite element stress analysis, thermal flow, human body implants, and more..

It has now got beyond us. One person does not have enough life to explore all the FreeCAD stuff out there.

I am thinking that, at the humble level I am going to use it, I am unlikely to need anything else!

I know that one can get into using Fusion360, but I didn't go there because my PC system is not Microsoft Windows. FreeCAD runs on all platforms (Windows, MacOS, Linux). I have been used to using various kinds of CAD for Electromagnetic Simulation, which are not directly for mechanical modeling, but do, of course, have physical metal shapes in their structures. I had a little play with SolidWorks, but I never got to go the whole learning curve with it, because retirement happily intervened.

For my needs, it's only simple models, and I use the TechDraw workbench to print out some dimensioned views to get grubby in the shop. Of course, FreeCAD kept evolving, all down to a genius crowd contributing faster than the main issue could keep up. Every kind of feature they love, if it's not there, they code it and post it. The best of these get incorporated into the main download, so the third-party tools, while they still can work, become obselete.

So now ..

Just how good do you want it to get?

The whole file is freely downloadable from GrabCad.

The step-by-step video is --> HERE

The chap who posts it is from Joko Engineering.

The tricks he gets up to to make sketches become great stuff with simple moves was, for me, a big shift in perspective.

So easy, not many clicks, - and he ends up with a great part

--> HERE

My attempt only needs two countershaft journals (floating about in space) and a correctly located mounting surface to help with the design of a motor adapter bracket. It needs a circular cut-out on a right-angle to mount my replacement motor (ex servomotor with full speed control). I decided to model the drive shaft and wheel, and a pulley of sorts (not seen yet) to help.

My FreeCAD model or the South Bend 9C Underneath drive Countershaft & Drive Wheel.

The real wheel is here (for comparison.

The Joko guy has done another (turbine rotor I think), where he does it side-by-side with SolidWorks, explaining the differences in actions and features.

Clearly now, this free, open source program has gone far beyond the critical point where it takes on a life of it's own. No matter what the field! I can see architecture, mechanical engineering, aeronautical airfoil design, robotics, finite element stress analysis, thermal flow, human body implants, and more..

It has now got beyond us. One person does not have enough life to explore all the FreeCAD stuff out there.

I am thinking that, at the humble level I am going to use it, I am unlikely to need anything else!

Last edited: