- Joined

- Jun 26, 2018

- Messages

- 1,733

Hey all,

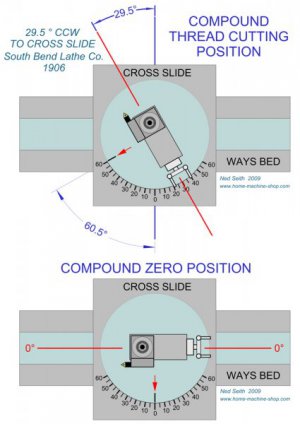

I have had my G0602z for over a year and finally have been playing with threading. Compound set at 29.5 degrees....threading tool is 60° and used a gauge to make sure it is set with work piece. Not backlash on my slides doing 12tpi on mild hot rolled 1/2" stock. My first scribe line looked good and I I did the reverse direction/ no disengage half nut. It seemed to be slightly scribing in two places right next to each other. My final product looked closed to metric 2.0 threads but we're very thin. Though there is no slop anywhere...there is on the leadscrew...but not how it connects to compound slide, but within the change gears. Lash adjustment is as tight as I can get it....but there is ample back and forth play within the gears. I'll post a picture of threads on a moment. Thoughts?

I have had my G0602z for over a year and finally have been playing with threading. Compound set at 29.5 degrees....threading tool is 60° and used a gauge to make sure it is set with work piece. Not backlash on my slides doing 12tpi on mild hot rolled 1/2" stock. My first scribe line looked good and I I did the reverse direction/ no disengage half nut. It seemed to be slightly scribing in two places right next to each other. My final product looked closed to metric 2.0 threads but we're very thin. Though there is no slop anywhere...there is on the leadscrew...but not how it connects to compound slide, but within the change gears. Lash adjustment is as tight as I can get it....but there is ample back and forth play within the gears. I'll post a picture of threads on a moment. Thoughts?