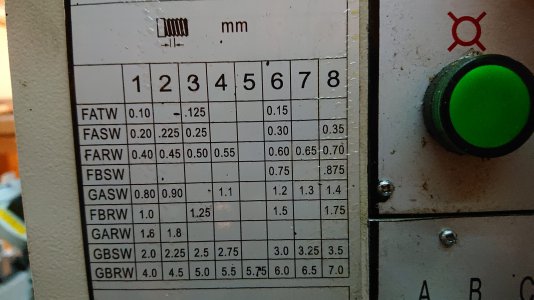

I'm trying to single-point an M4 screw thread on my G0709. It says that FARW8 is 0.7mm thread pitch. But it's actually cutting a much finer pitch, so fine that I'm having trouble gauging it accurately. Maybe 0.4 or 0.45 mm?

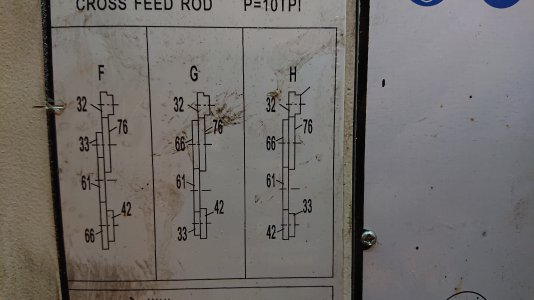

I have definitely confirmed, twice, that my change gears are in the F configuration. I have made sure that the ABC, RST, and WXY knobs only move to point to the three indexes, and engage at each index. I'm not sure how to confirm that the 1-8 knob is really in the 8 position since it rotates infinitely, without a stop, but it looked like it cut an even finer pitch when I moved it to 2, and FARW2 is the setting for 0.45mm pitch.

The exploded diagram for the gearbox in the manual is less than complete for demonstrating how the gearbox works. I'd appreciate suggestions for diagnosing the problem. The gear train in it is a mystery to me.

Thanks for any insight!

I have definitely confirmed, twice, that my change gears are in the F configuration. I have made sure that the ABC, RST, and WXY knobs only move to point to the three indexes, and engage at each index. I'm not sure how to confirm that the 1-8 knob is really in the 8 position since it rotates infinitely, without a stop, but it looked like it cut an even finer pitch when I moved it to 2, and FARW2 is the setting for 0.45mm pitch.

The exploded diagram for the gearbox in the manual is less than complete for demonstrating how the gearbox works. I'd appreciate suggestions for diagnosing the problem. The gear train in it is a mystery to me.

Thanks for any insight!