I'm trying to put the clough42 ELS on my G0709, using a servo drive. The servo can run the leadscrew fine, and when I have tested it can move the carriage very fast.

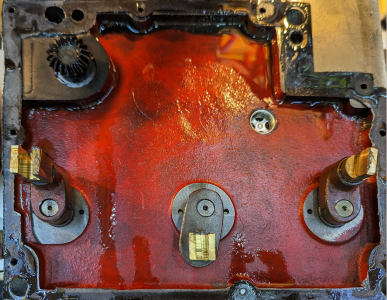

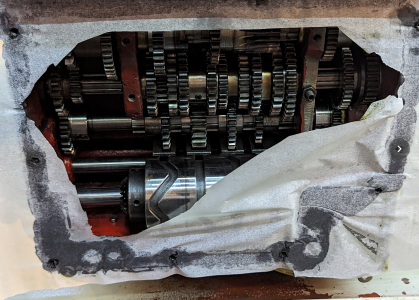

However, the feed bar is much stiffer. Of course I've never noticed that when running the change gears, but when I hook up the servo, any gearbox setting that engages the feed bar causes the servo to overcurrent and stop.

Hand-turning the gearbox input, I can tell that the feed screw does not turn freely.

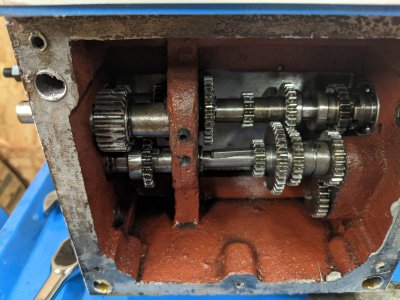

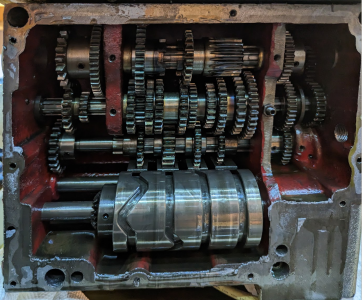

What is the procedure for removing the gearbox to clean it out?

It wasn't that hard to mostly disassemble the headstock when I replaced the main spindle bearings, but the drawings don't give me a good sense of how the gearbox goes together.

I guess ultimately I could instead remove the gearbox and replace it with a custom mount for the ELS, but that's not where I want to start. ☺

Thanks!

However, the feed bar is much stiffer. Of course I've never noticed that when running the change gears, but when I hook up the servo, any gearbox setting that engages the feed bar causes the servo to overcurrent and stop.

Hand-turning the gearbox input, I can tell that the feed screw does not turn freely.

What is the procedure for removing the gearbox to clean it out?

It wasn't that hard to mostly disassemble the headstock when I replaced the main spindle bearings, but the drawings don't give me a good sense of how the gearbox goes together.

I guess ultimately I could instead remove the gearbox and replace it with a custom mount for the ELS, but that's not where I want to start. ☺

Thanks!