I just a new floor in my garage and would like some ideas about how to lay out machines when I move everything back in.

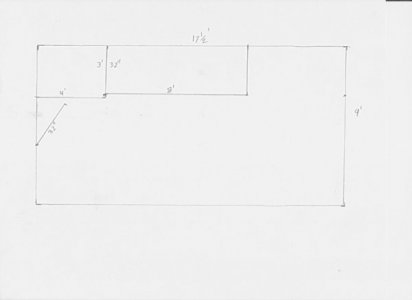

The space is 19' x 20'. I have a bunch of tables. a 12' wood workbench & an 8' wood work bench. 2 small sized metals benches on casters. I have the normal shop stuff, welder, small band saw, mill and lathe, belt grinder and also a surface grinder. I think the open space in the middle needs to be utilized, machines are work bench? I hope to be dropping a few air lines from the ceiling as well as some electrical. What are your thoughts on wall shelves? Do you guys use a lot of them?

Thanks for the ideas.

The space is 19' x 20'. I have a bunch of tables. a 12' wood workbench & an 8' wood work bench. 2 small sized metals benches on casters. I have the normal shop stuff, welder, small band saw, mill and lathe, belt grinder and also a surface grinder. I think the open space in the middle needs to be utilized, machines are work bench? I hope to be dropping a few air lines from the ceiling as well as some electrical. What are your thoughts on wall shelves? Do you guys use a lot of them?

Thanks for the ideas.