- Joined

- Nov 21, 2021

- Messages

- 35

Does writing software count as a "Project"? Well if it does I would like to tell you about a program I wrote for lathe users. RideTheGearTrain.com

It was designed to tell you how to set up the gear train to cut any thread. When it runs it usually gives you a long list of different ways you can set up your gear train. Beside each setup there is a button labeled DRAW. Click that and it produces a scale drawing of the gear train so that you can spot any problems that might occur.

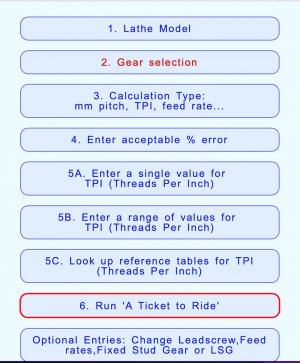

The data input is in 5 steps and then you run the program.

(1) First choose your lathe.

(2) Enter the set of gears that you own.

(3) Choose what type of thread you need: metric, imperial or feed rate

(4) Enter the % error you are willing to accept in the final thread. It may be zero or perhaps 2%.

(5) Enter the pitch of the thread you require. Actually there are 3 ways you can do this:

(5A) Simply enter the pitch or TPI

(5B) Enter a range of values to produce tables

(5C) Look up a reference table eg metric or UNC etc.

(6) Finally click RUN.

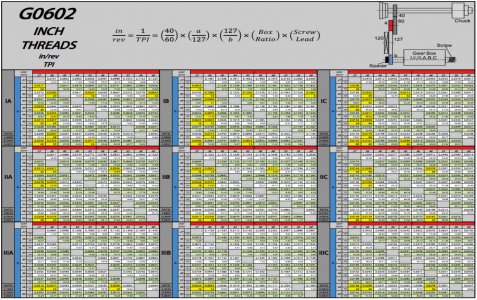

If you choose option 5C the reference tables provide a lot of extra information which allows the program to display "Thread Specifications" after the list of gear trains. This includes two tables of possible metric or imperial drill sizes that could be used for the thread you chose. Not just a single drill size that most tables give you. I have been adding calculation of the stress on the bolt and thread when tightened to a given torque (under construction).

It will work for any lathe without a gearbox, including mini-lathes. For lathes with a gearbox it needs to know the gear ratios. There is a list of about 25 lathes with gearbox data included. It was originally written for Boxford and other SouthBend 9A clones so if you have a clone choose a "Norton" gearbox. Myford is included and so are a few other models like Colchester, Chester, Nile, Hendley, Precision Mathews etc. If you want your lathe added please contact me or look up "Custom Gearbox" at the end of the list of lathes.

There are extensive help files with help button beside each input box.

There are 3 Youtube tutorials listed below the menu.

My email address is listed at the top of the info, above the menu.

Keep in mind that I am not an engineer - my only training was 4 years of engineering in High School with my father as the teacher.

Let me know if you have any questions or discover any problems or flaws.

PS it does not cost you a cent and there are no hidden costs.

I hope you find this useful. Enjoy!

Evan

It was designed to tell you how to set up the gear train to cut any thread. When it runs it usually gives you a long list of different ways you can set up your gear train. Beside each setup there is a button labeled DRAW. Click that and it produces a scale drawing of the gear train so that you can spot any problems that might occur.

The data input is in 5 steps and then you run the program.

(1) First choose your lathe.

(2) Enter the set of gears that you own.

(3) Choose what type of thread you need: metric, imperial or feed rate

(4) Enter the % error you are willing to accept in the final thread. It may be zero or perhaps 2%.

(5) Enter the pitch of the thread you require. Actually there are 3 ways you can do this:

(5A) Simply enter the pitch or TPI

(5B) Enter a range of values to produce tables

(5C) Look up a reference table eg metric or UNC etc.

(6) Finally click RUN.

If you choose option 5C the reference tables provide a lot of extra information which allows the program to display "Thread Specifications" after the list of gear trains. This includes two tables of possible metric or imperial drill sizes that could be used for the thread you chose. Not just a single drill size that most tables give you. I have been adding calculation of the stress on the bolt and thread when tightened to a given torque (under construction).

It will work for any lathe without a gearbox, including mini-lathes. For lathes with a gearbox it needs to know the gear ratios. There is a list of about 25 lathes with gearbox data included. It was originally written for Boxford and other SouthBend 9A clones so if you have a clone choose a "Norton" gearbox. Myford is included and so are a few other models like Colchester, Chester, Nile, Hendley, Precision Mathews etc. If you want your lathe added please contact me or look up "Custom Gearbox" at the end of the list of lathes.

There are extensive help files with help button beside each input box.

There are 3 Youtube tutorials listed below the menu.

My email address is listed at the top of the info, above the menu.

Keep in mind that I am not an engineer - my only training was 4 years of engineering in High School with my father as the teacher.

Let me know if you have any questions or discover any problems or flaws.

PS it does not cost you a cent and there are no hidden costs.

I hope you find this useful. Enjoy!

Evan