There are a number of options. It sort of depends on what resources you have available and what you are hoping to accomplish. It is pretty easy to spend more on fixing up a machine than it would cost to purchase a machine that would do many of the things you want. Certainly, you can put a variable speed drive on (3 phase or DC). The torque will drop off (if you slow it way down, it will drop of quite a bit - mainly because of the difficulty in cooling it).

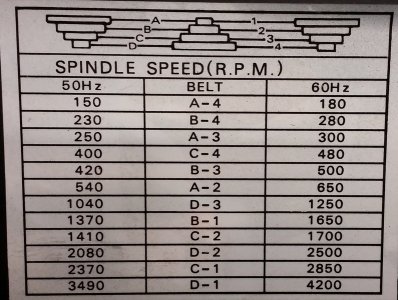

If you go with a 6 pole motor (1150 rpm), that is physically quite a bit larger - but that would get you down to about 350 rpm (and full torque capability). You could make your own larger pulley (which still gives you plenty of torque) - how much room do you have? You could go with a DC motor & drive - often these motors are fairly high speed, so you get variable speed - but you may need an intermediate shaft to get some decent torque back. You could go with a VFD and a 3 phase motor - recommend a 6 pole motor and/or upsizing the motor to preseve torque at the low end (a very nice solution, but if you pay store price for the components it will exceed the price of a good used HD drill press). You could set up an intermediate shaft - which works great, lots of speed selections, good torque (until that wee little belt slips - unless you go to a cog belt as the second belt), but a little fussy to set up and make guards for.

I had the same problem as you (too fast a drill press). I had an 11" Rockwell drill press (1/3 HP). I put a 1/2 HP DC motor on it. It was constantly popping the over current protection.

I was able to obtain a good HD Rockwell at auction for $375. It came with a 3 phase, 6 pole motor (1150 rpm) and quite a large step pulley on the spindle. I solved the 3 phase requirement with a cast off VFD (meaning old, free and still works, albiet noisy). I then spend quite a few hours engaged in "recreational chipping" to fit the drive in a nice enclosure, make up a pretty little mount for said enclosure, wire in the 3-wire stop/start to the drive - the result is great, but I was starting with something that was well along in achieving a slow drilling speed.

I no longer have that 11" DP. I got a nice 14", which is sort of fast, but combined with the 17" the bases are covered.

Your original question was, to ask what others here would do. First of all, just use the machine as is - sure it is a bit fast, but does it really cause you problems? At worst you may get a bit more practice sharpening drill bits.

Second, I would keep an eye out for lower speed motors (single phase or 3 phase). 3rd, I'd keep an eye out for a HD drill press (running a light duty drill press at low speed, is still a light weight drill press). 4th, I'd start thinking about setting up an intermediate shaft (picking up materials etc. on the cheap) - after a few years of "First", if "second" or "3rd" had not worked out and I found there was problems - only then would I modify the drill press.

Let us know what you work out.