Ok, I had something stashed away just waiting to bite me in the ass, and it did.

Working on my Prazi lathe retrofitting it with a custom crafter variable speed drive the other day I needed to modify the motor mount I made.

I needed to remove .200 off of the mounting end to help with belt tension and subsequently retap the existing three holes deeper by the same amount.

When I set this shop up in the generator room in the basement I was using the tools from my first Kennedy box I got during my apprenticeship.

This toolbox was like a time capsule as I had brought it home decades ago along with all of its contents and set it down in the basement and forgot about it.

I was thrilled to rediscover all of the specialized tooling I had for different difficult applications. Specialized taps, deburring tools, riffler files, it was like receiving a boatload of free tooling and measuring tools.

So I milled the motor bracket and was eager to get this finished and remounted to try this new addition out.

I grabbed a1/4-20 tap and began tapping the holes a little deeper, no big deal except the middle hole was an interrupted cut as half of it was milled away.

Again, no big deal as I have been in this situation dozens of times and never broke a tap.

Now if I haven’t bored you to tears yet, here’s the part where something from the past traveled through time to bite me in the ass.

Sometime around the year 2000 we changed vendors at work and got our trusted TRW and Greenfield taps replaced with some type of glass hard Japanese branded taps.

These things were so friggin hard they would break if you even breathed on them too hard. Turns out they were a specialized tap for cnc tapping operation and should have never been sent to us in the first place.

I mean I have taps that I have flexed a dozen times, where you can literally see and feel the tap acting springy well before breaking.

Not this crappy tap.

So unbeknownst to me there was one of these evil devil taps in amongst my tools in this long forgotten box and I picked it up out of 3-4 others just like it.

First hole went well. The second hole provided some limited resistance when the flutes were cutting on the remaining side of the hole, but this really didn’t seem or feel out of the ordinary, as like I said, btdt.

Then it happened, a tiny little, near subaudible “snick” and my mind just went reeling back in tile to the last time this happened to me.

Picture calculation’s, drawings and mathematical formulations flashing through my minds eye in a brief panic.

I knew just by the feel and hearing that sound again, that I broke one of those long forgotten **** taps.

And these don’t just break like a good tap will. Oh no, they break off well down inside the hole so you can’t even back the stub end out without ruining the hole.

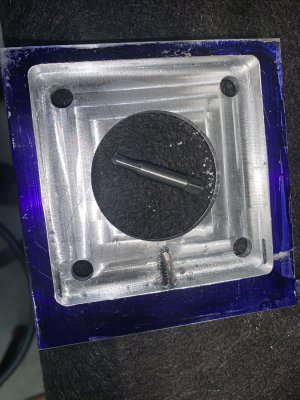

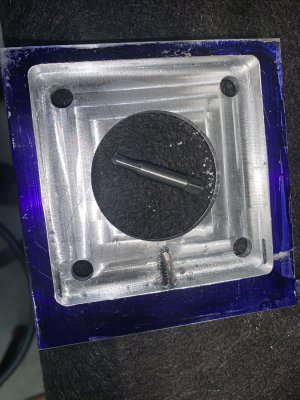

Lookit.

This is after I just pried sideways on the tap to break it off and hope for the best.

I was able to shatter the protruding tip off with a chisel and do the same for most of the broken end and grind the rest below the surface.

Meh, three bolts was overkill anyway.

Blunder? Stashing one of these ****ty glass taps away rather than chucking it in the scrap tub.

Thanks for reading my novel.