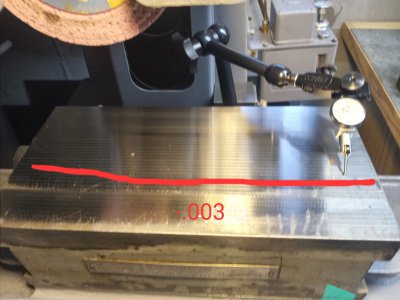

Hello trying to see the best way to speed up this process. Boyar shultz 612 with electromagnetic chuck. Im grinding the chuck flat but the lower 1/3 slopes down about .003. I'm taking light cuts about .0002 and redressing ever other pass. The chuck is on when grinding. At my pace this will take forever. Can I just go deeper like .001 let it cool and then lighten it up for a finsh cut

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Grinding the chuck

- Thread starter BCwoods

- Start date

- Joined

- Feb 2, 2013

- Messages

- 3,627

you might wish to survey the surface grinder before committing to grinding the chuck.

if the ways are worn, there is no good reason to grind the chuck until you know the ways are good

if the ways are worn, there is no good reason to grind the chuck until you know the ways are good

I should have elaborated. Ways are good, table is within .0001 x and y (won't make that mistake again) and this chuck did not come with the grinder. It looks like someone had started to grind it and that's why it's out this much. My lack of expertise does not tell me if I should just keep at .0002 or 3 or just try deeper. Which of course can heat things up and cause more issues

- Joined

- Jan 7, 2016

- Messages

- 3,279

How ironic. I was just reviewing Suburban Tool's video on this exact subject. I'm afraid I don't really have any advice. I have a Bridgeport 815 that I need to evaluate its degree of precison capability, which may include grinding the chuck.

- Joined

- Feb 1, 2018

- Messages

- 1,868

Turn on the magnet and use coolant. What is happening the chuck is getting hot and expanding you grind it when it's expanded and when it cools off it goes low. Also how are you dressing the wheel? The wheel grit should be no higher then 46, dress with a sharp diamond and take a .002" pass and stop. If your moving it back and forth multiple times back and forth not removing any grit, your dulling the wheel and a dull wheel grinds hot. Use a infa red temp taker and if the hear goes up, stop and let it cool off. A spray coolant is best, a spray pump bottle is better then nothing.

It’s not hard to rig up a 5-gallon bucket with a cheap pump for coolant. It will make a big difference especially for something big like a chuck.

When I ground my chuck with coolant, taking 0.0005” passes was fine. Mine was bowed considerably, like 0.007” high on the ends, so it took a bit of work to flatten it.

When I ground my chuck with coolant, taking 0.0005” passes was fine. Mine was bowed considerably, like 0.007” high on the ends, so it took a bit of work to flatten it.

Last edited: