ISO certification means an auditor came in and reviewed process control paperwork (for example) and the entity being audited shows evidence that they are following their documented processes. Basically document what you do, do what you document. Doesn't mean the product is good or not, just that it was made by following the documented processes.

I used to work at the Lansing Car Assembly plant in Lansing, MI. We had an ISO audit coming up; production was worried about passing a few of the documented checks. One in particular was checking the height and width of the robotically applied urethane bead to the windshield. Process control paperwork said the bead had to be between 8 - 14 mm tall, checked once at the start and end of the shift. Our tool room made up throw away Delrin step gauges at those heights. ISO: How do you know the step gauges are truly 8 mm and 14 mm tall? We check them with a calipers. How do you know the calipers are accurate? They are zero'd on an 8 mm and/or 14 mm gauge block before checking the blocks. How do you know the gauge blocks are correct? We didn't have certification letters from Mitutoyo or whoever made the blocks. We could buy the specific standards from Starrett for around $60 each. So, our elegant solution was to simply remove the process control document. We still did the check to ensure we were producing a quality car without windshield leaks, but the process control document was removed from the books until the audit was over. Passed our ISO certs with flying colors.

IMHO ISO isn't a bad thing, but it's highly overrated. Just another group out there who created their own market to make money. Potentially, no value added to the end product, smart people can easily get certified but it doesn't mean the products are any good. Conversely, non-ISO products can be fine. I'd rather buy something from a long-standing USA company without ISO certification than a start up new Chinese company with ISO certs. Proof in the pudding is the long-term success of the company staying in business; customers figure out pretty quickly if they're buying garbage and the bad producers go away.

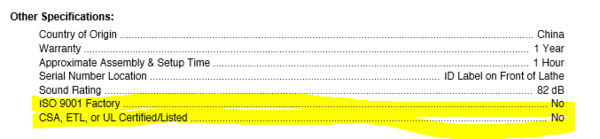

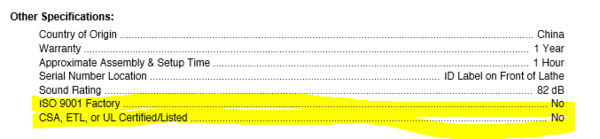

Here's a snip of the Grizzly G0709 lathe manual. Most of Grizzly's lathes are produced from non-ISO, non-UL certified factories. Many of us have lathes from Grizzly and are very happy with our non-ISO factory produced machines.

Sorry for the soap box rant . . .

Bruce