This is my first post here. I read somewhere that it is acceptable to ask "dumb questions" here so, please, let me please get those out of the way first. I have been trying to compare lathes lately, and I was trying to compare allowable feed rates. That resulted in my question:

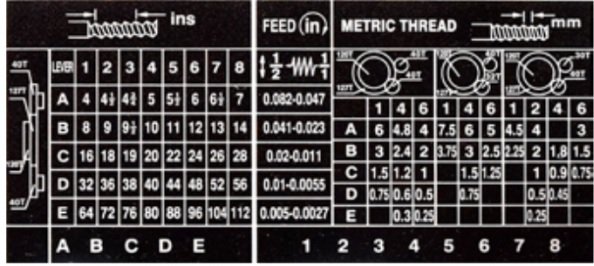

1. Does the quick change gear box drive both the feed screw and the lead screw to push the carriage at the same rate along the longitudinal axis, when it is set at a given setting? My interest in this question is that I want to know is the extent of feed rates that are available. On a comparable PM machine with 12" swing, it appeared there were about 6 rates available, with the smallest being about .002"/rev. This makes me think that the answer to my question is likely"no", and thus I don't know the feed rates that are available on the G4003. If the answer is yes, than the feed rates correspond to the thread capabilities, which range from less than .001"/rev to .031"/rev. or so. I was thinking if would be advantageous to have the smaller feed rate available (less than .002/rev.). I'm a "newbie", What does the voice of experience say?

Incidentally, I used a lathe in high school, where I happily took all of the shop classes. I may have used a Jet 1240P lathe at that time (because they look familiar). Since then, and in the last month or two I have watched about 200 videos by MrPete222 and ThisOldTony, et. al. Okay, next question.

2. From the title of this message, I have obviously been drawn to looking at the G4003. Then I noticed, just on the next page of the catalog, that after you toss in the stand, and separate shipping, that the G4003G comes in perhaps at an even (slightly) better price. The G4003 has a D1-4 spindle and a smaller bore than the G4003G which has a D1-5 spindle. I don't have an interest in making guns (and I know that the G4003G seems to be targeted (a little pun there) toward gun-makers). What do you make of this-and/or which would you choose?

3. Am I likely to find a Clausing lathe (1300/1301 or other) which runs on single phase 220v (which I have available)? I've gotta say, I find some of the older lathes, like ones named "Colchester", to be handsome machines. FWIW, I can tell you for sure that my wife doesn't (see it). : )

Thank you for any kind guidance and assistance that you can offer me.

Bill_729

1. Does the quick change gear box drive both the feed screw and the lead screw to push the carriage at the same rate along the longitudinal axis, when it is set at a given setting? My interest in this question is that I want to know is the extent of feed rates that are available. On a comparable PM machine with 12" swing, it appeared there were about 6 rates available, with the smallest being about .002"/rev. This makes me think that the answer to my question is likely"no", and thus I don't know the feed rates that are available on the G4003. If the answer is yes, than the feed rates correspond to the thread capabilities, which range from less than .001"/rev to .031"/rev. or so. I was thinking if would be advantageous to have the smaller feed rate available (less than .002/rev.). I'm a "newbie", What does the voice of experience say?

Incidentally, I used a lathe in high school, where I happily took all of the shop classes. I may have used a Jet 1240P lathe at that time (because they look familiar). Since then, and in the last month or two I have watched about 200 videos by MrPete222 and ThisOldTony, et. al. Okay, next question.

2. From the title of this message, I have obviously been drawn to looking at the G4003. Then I noticed, just on the next page of the catalog, that after you toss in the stand, and separate shipping, that the G4003G comes in perhaps at an even (slightly) better price. The G4003 has a D1-4 spindle and a smaller bore than the G4003G which has a D1-5 spindle. I don't have an interest in making guns (and I know that the G4003G seems to be targeted (a little pun there) toward gun-makers). What do you make of this-and/or which would you choose?

3. Am I likely to find a Clausing lathe (1300/1301 or other) which runs on single phase 220v (which I have available)? I've gotta say, I find some of the older lathes, like ones named "Colchester", to be handsome machines. FWIW, I can tell you for sure that my wife doesn't (see it). : )

Thank you for any kind guidance and assistance that you can offer me.

Bill_729