- Joined

- Mar 26, 2018

- Messages

- 8,407

This is not a new subject. These grinders are known for their poor quality wheels and sticking tool rests.

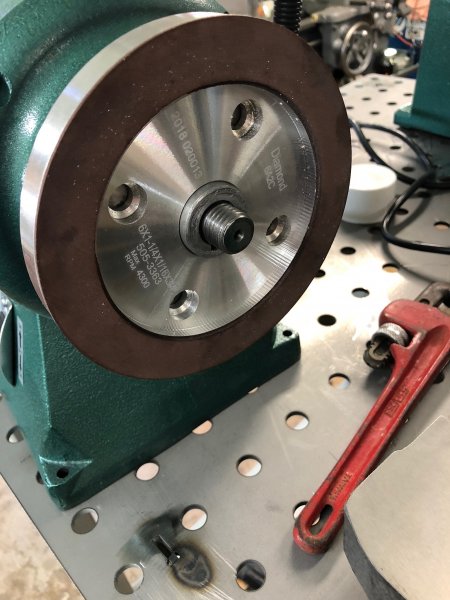

I replaced the grinding wheels with one diamond and one good quality “green wheel”.

I followed the advice from YouTube to make this Baldor knock off worth a darn.

Squaring the protractors, removing paint where it contacts the sliding protractors, removing burs and providing clearance where. Required.

I assumed, “type 50” grinding wheels would fit this machine since the manual’s Instructions did not say, modifications required. No, I had to remove about .010” from the aluminum backing plate on the well made diamond wheel. I also had to increase the ID of the CGW wheel for proper mounting clearance.

Just be aware, I was expecting to perform these upgrades. I have a very smooth, capable machine now.

I saved hundreds of $$$$&$ but I did have to spend a few hours on it.

I replaced the grinding wheels with one diamond and one good quality “green wheel”.

I followed the advice from YouTube to make this Baldor knock off worth a darn.

Squaring the protractors, removing paint where it contacts the sliding protractors, removing burs and providing clearance where. Required.

I assumed, “type 50” grinding wheels would fit this machine since the manual’s Instructions did not say, modifications required. No, I had to remove about .010” from the aluminum backing plate on the well made diamond wheel. I also had to increase the ID of the CGW wheel for proper mounting clearance.

Just be aware, I was expecting to perform these upgrades. I have a very smooth, capable machine now.

I saved hundreds of $$$$&$ but I did have to spend a few hours on it.