- Joined

- Sep 28, 2013

- Messages

- 40

Long time ago I visited the workshop of an electrical engineer. He had every machine you could think of. Metalworking, wood etc all layed out in his basement. He was selling something and I was checking it out.

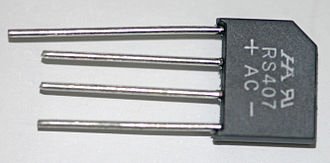

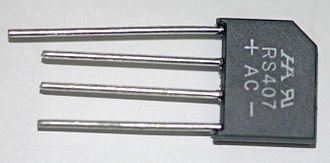

His workbench though was for electronics. He had capacitors? I think, the round tube jobbos with wires at each end. He was building what looked like an accordian of these things all wired together. He called it a Bridge. All his machines were equipped with them. Variable speed.

He had hundreds of those parts segregated in bins. Middle container was whatever the standard part was called. Like it was a "100" that was commonly used in all electronics. However he knew that the actual output was subject to manufacturing variability. He measured somehow each "100" component and the +/- range was maybe -5 to +10 of the stated spec.

And by wiring a group from -5 through the highest +10 maybe, that was all he needed to make all motors VS.

This was a house in Chicago but I don't recall if the motors were single phase 120v or three phase or whatever. My understanding was his Bridge was the only mod needed. He proceeded to power up his table saw through slow speeds to full on. Scared me. It was whistling.

What can you tell me about that technology. He made these to sell to other engineers so it was common in the early '70s. I've met some interesting people in my life and he was special. If this rings a bell or is common technology let me know?

Merry Christmas to you good folks...

Bob

His workbench though was for electronics. He had capacitors? I think, the round tube jobbos with wires at each end. He was building what looked like an accordian of these things all wired together. He called it a Bridge. All his machines were equipped with them. Variable speed.

He had hundreds of those parts segregated in bins. Middle container was whatever the standard part was called. Like it was a "100" that was commonly used in all electronics. However he knew that the actual output was subject to manufacturing variability. He measured somehow each "100" component and the +/- range was maybe -5 to +10 of the stated spec.

And by wiring a group from -5 through the highest +10 maybe, that was all he needed to make all motors VS.

This was a house in Chicago but I don't recall if the motors were single phase 120v or three phase or whatever. My understanding was his Bridge was the only mod needed. He proceeded to power up his table saw through slow speeds to full on. Scared me. It was whistling.

What can you tell me about that technology. He made these to sell to other engineers so it was common in the early '70s. I've met some interesting people in my life and he was special. If this rings a bell or is common technology let me know?

Merry Christmas to you good folks...

Bob