- Joined

- Jul 8, 2021

- Messages

- 20

Gday,

I previously introduced myself and my machine in the welcome section but thought I'd start a thread here for my lathe. Apologies for any repetition.

I am now the proud owner of a HAFCO AL350B.

Year: 1988

Country: Taiwan (Sold in Australia under the label HAFCO)

Swing: 12 in.

Between Centres: 27 in. as per catalogue OR 24 in. as per original manual

Belt drive

Included was the original sales brochure (and price AUD), link here.

I also received the original manual and inspection record, link here.

I also got a 4 jaw, travelling steady, tailstock, faceplate, dead centres, small amount of tooling.

The manual implies that it is a rebranded Liang Dei (LD), but there are no markings on the lathe to confirm this so can't be 100% sure. It is very similar to the HAFCO AL900A/AL900B. I think the only difference may be bed length. I note there is another thread on the AL900A here.

I am in the process of giving it a good clean & lube and fitting an E-stop before I fire it up for the first time.

My first question - lubrication

Firstly the spindle bearings. The manual provides no guidance here. The two bearings sit in individual oil baths, filled via two holes under the headstock cover (see photos). Draining appears to be via the front sight glasses.

Can anybody with a similar machine provide some guidance on the grade of oil for the spindle bearings? I have read conflicting information from the various manuals available for these Taiwanese lathes. Some manuals specify the equivalent of ISO32 (TIDA/Jet) while others (Grizzly) recommend ISO68. I have both grades available in hydraulic oil.

I plan to use ISO68 hydraulic oil on all the other lubrication points other than the ways for which I have a dedicated way oil.

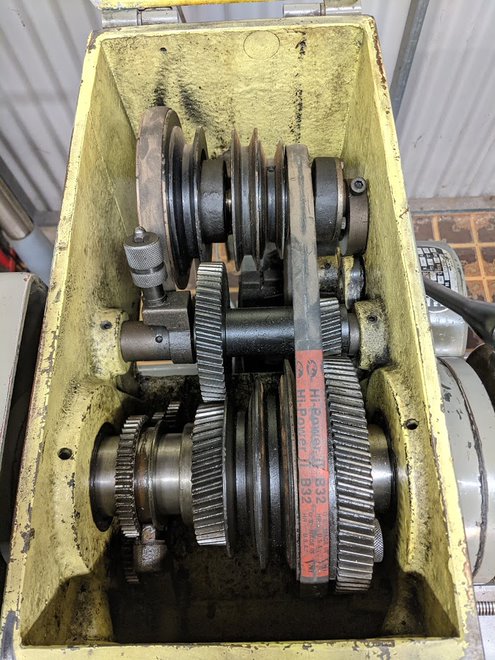

The quick change gear box I'm unsure about. It has the single lube point that then drips through the various holes onto the gears. I'm also leaning towards ISO68 hydraulic oil.

I'd appreciate your input.

Looking forward to making some chips...eventually.

Adam

I previously introduced myself and my machine in the welcome section but thought I'd start a thread here for my lathe. Apologies for any repetition.

I am now the proud owner of a HAFCO AL350B.

Year: 1988

Country: Taiwan (Sold in Australia under the label HAFCO)

Swing: 12 in.

Between Centres: 27 in. as per catalogue OR 24 in. as per original manual

Belt drive

Included was the original sales brochure (and price AUD), link here.

I also received the original manual and inspection record, link here.

I also got a 4 jaw, travelling steady, tailstock, faceplate, dead centres, small amount of tooling.

The manual implies that it is a rebranded Liang Dei (LD), but there are no markings on the lathe to confirm this so can't be 100% sure. It is very similar to the HAFCO AL900A/AL900B. I think the only difference may be bed length. I note there is another thread on the AL900A here.

I am in the process of giving it a good clean & lube and fitting an E-stop before I fire it up for the first time.

My first question - lubrication

Firstly the spindle bearings. The manual provides no guidance here. The two bearings sit in individual oil baths, filled via two holes under the headstock cover (see photos). Draining appears to be via the front sight glasses.

Can anybody with a similar machine provide some guidance on the grade of oil for the spindle bearings? I have read conflicting information from the various manuals available for these Taiwanese lathes. Some manuals specify the equivalent of ISO32 (TIDA/Jet) while others (Grizzly) recommend ISO68. I have both grades available in hydraulic oil.

I plan to use ISO68 hydraulic oil on all the other lubrication points other than the ways for which I have a dedicated way oil.

The quick change gear box I'm unsure about. It has the single lube point that then drips through the various holes onto the gears. I'm also leaning towards ISO68 hydraulic oil.

I'd appreciate your input.

Looking forward to making some chips...eventually.

Adam