- Joined

- Aug 29, 2019

- Messages

- 522

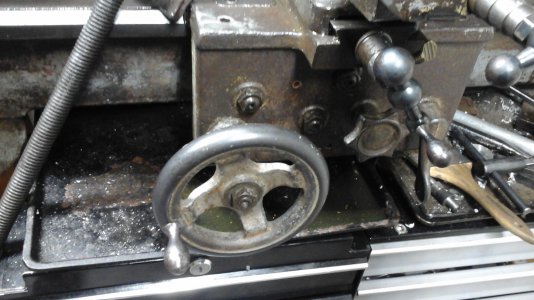

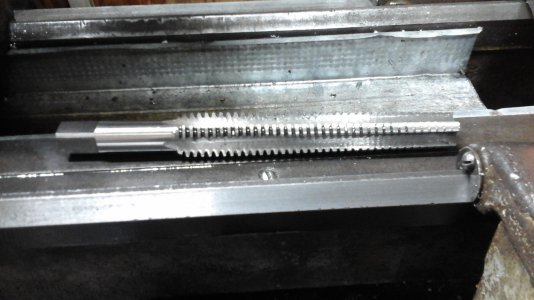

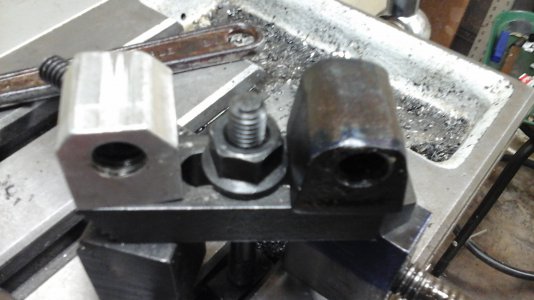

This is a repair of the Half Nut on my Clausing 100 lathe. I also made a new cast iron cross slide nut from cast iron as well. I finally got around to sawing the nut in half today and re assembling the apron to the Saddle and putting the lead screw back in it. To my great surprise and being tickled pink all works just as it should with new parts. I have pictures scattered everywhere including thumb drives -phone-tablet etc. So, bear with me if the pictures are not in order. I may even come back later and add more pictures as I find them. There is very little on these old lathes, so my intent is to post my success here to help others. Thanks for stopping by my thread.

Attachments

-

20221110_201650.jpg585.4 KB · Views: 21

20221110_201650.jpg585.4 KB · Views: 21 -

20221108_190955 - Copy.jpg825.9 KB · Views: 22

20221108_190955 - Copy.jpg825.9 KB · Views: 22 -

20221108_191036 - Copy.jpg852.1 KB · Views: 22

20221108_191036 - Copy.jpg852.1 KB · Views: 22 -

20221108_191041 - Copy.jpg817.9 KB · Views: 19

20221108_191041 - Copy.jpg817.9 KB · Views: 19 -

20221108_191053 - Copy.jpg736.8 KB · Views: 18

20221108_191053 - Copy.jpg736.8 KB · Views: 18 -

20221108_191123 - Copy.jpg824.8 KB · Views: 19

20221108_191123 - Copy.jpg824.8 KB · Views: 19 -

20221108_191130 - Copy.jpg781.7 KB · Views: 17

20221108_191130 - Copy.jpg781.7 KB · Views: 17 -

20221108_191214 - Copy.jpg690.7 KB · Views: 16

20221108_191214 - Copy.jpg690.7 KB · Views: 16 -

20221108_191251 - Copy.jpg739.1 KB · Views: 16

20221108_191251 - Copy.jpg739.1 KB · Views: 16 -

20221108_191256 - Copy.jpg644.6 KB · Views: 17

20221108_191256 - Copy.jpg644.6 KB · Views: 17 -

20221110_200036 - Copy.jpg785.2 KB · Views: 17

20221110_200036 - Copy.jpg785.2 KB · Views: 17 -

20221110_200036.jpg785.2 KB · Views: 17

20221110_200036.jpg785.2 KB · Views: 17 -

20221110_200045.jpg763.3 KB · Views: 17

20221110_200045.jpg763.3 KB · Views: 17 -

20221110_200059.jpg674.6 KB · Views: 16

20221110_200059.jpg674.6 KB · Views: 16 -

20221110_200241.jpg684 KB · Views: 15

20221110_200241.jpg684 KB · Views: 15 -

20221110_200309.jpg677.9 KB · Views: 14

20221110_200309.jpg677.9 KB · Views: 14 -

20221110_200313.jpg635.7 KB · Views: 14

20221110_200313.jpg635.7 KB · Views: 14 -

20221110_200314.jpg642.5 KB · Views: 13

20221110_200314.jpg642.5 KB · Views: 13 -

20221110_201550.jpg645 KB · Views: 13

20221110_201550.jpg645 KB · Views: 13 -

20221110_201606.jpg826.7 KB · Views: 19

20221110_201606.jpg826.7 KB · Views: 19