- Joined

- Oct 4, 2016

- Messages

- 7,025

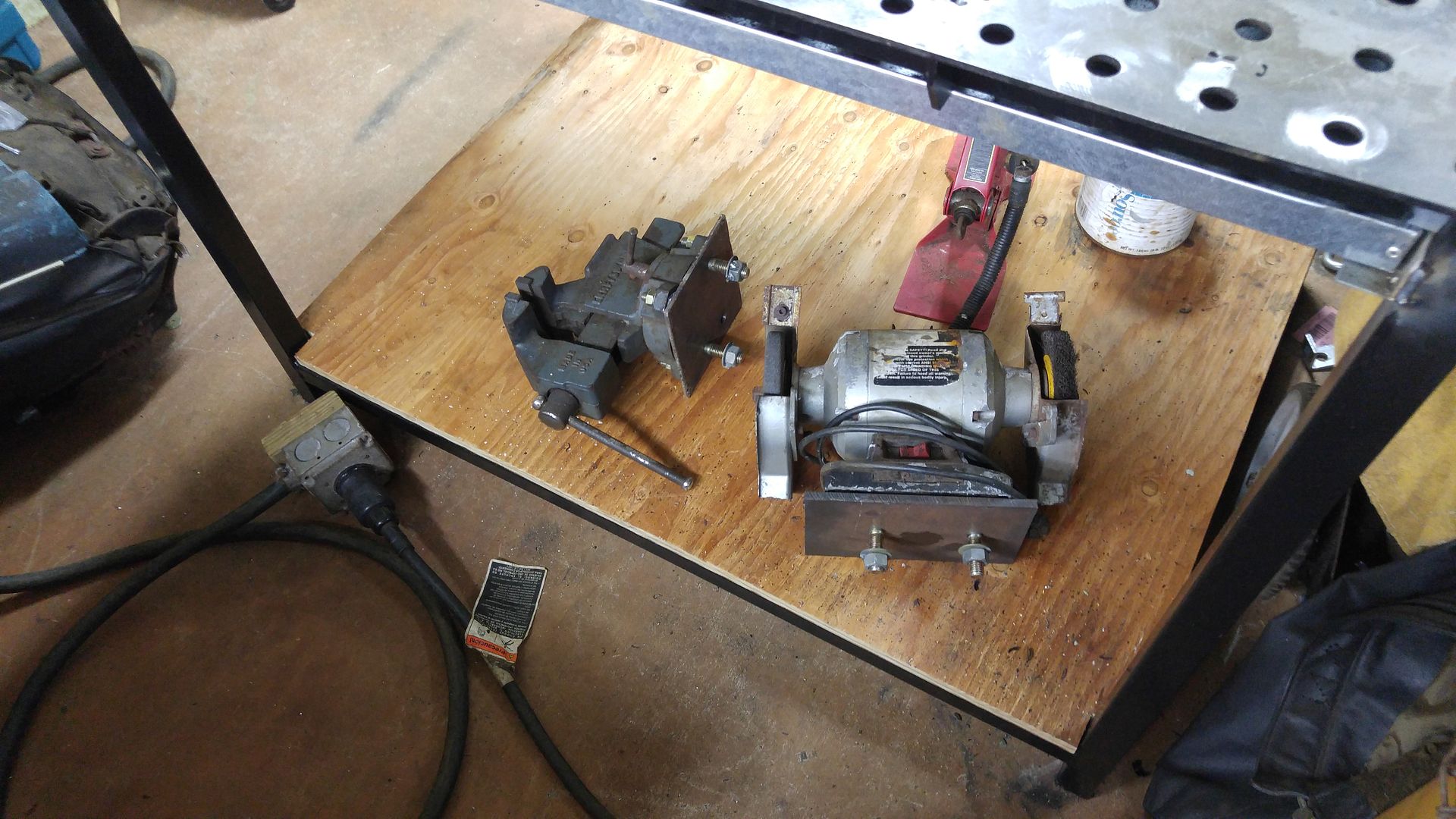

I have a 1/2" plate that has some chunks taken out of it, and maybe one factory edge. I'm thinking of squaring the plate by taking off the odd shaped piece, and making a plate to hammer on for the welding table. 11x13 (nominal) not square in the picture. I'm wondering if that would be utilitarian enough, without getting too heavy? Not sure what to do with the 24x29 inch leftover. I'm becoming a hoarder, there is also a 6'x5"x1" length of MS stock.( no picture)