- Joined

- Oct 24, 2013

- Messages

- 149

I've needed a saw to cut sheet metal, aluminum, & plastic for a long time but had to get by with either a hack saw or hand-held jig or saber saw. Occasionally, in a pinch, I've taped the trigger speed control for the saber saw so it stayed on & clamped it in a vise with the blade & platen up to make some cuts. I considered buying a vertical band saw for this kind of work but decided I could save money & space by building a fixture to hold the saber saw securely upside down & the following pics should how I went about it.

The first pic shows the table top mostly. I'd like to say I did all the machining here but, alas, I don't have a Blanchard or Mattison surface grinder to clean up the surface & my LMS 3960 Mini MIll had neither the length of cut nor throat capacity to square it up or do the other necessary work so I took it to a local machine shop after I did the design & layout. I was able to drill all the holes, elongate some & mill all the frame pieces to length, however.

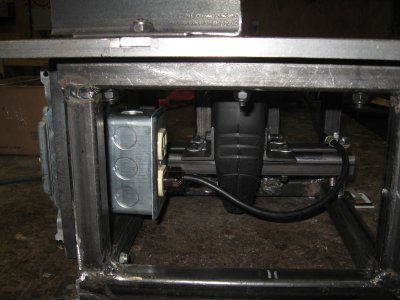

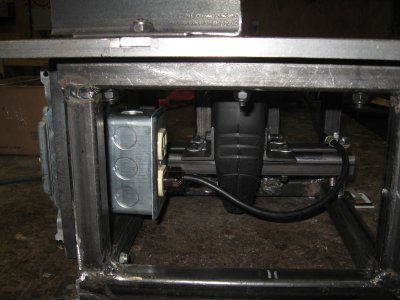

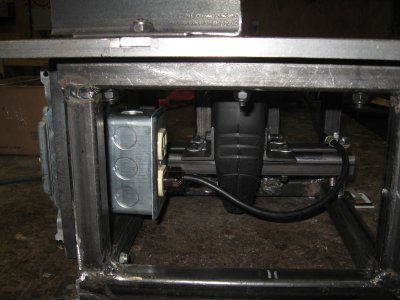

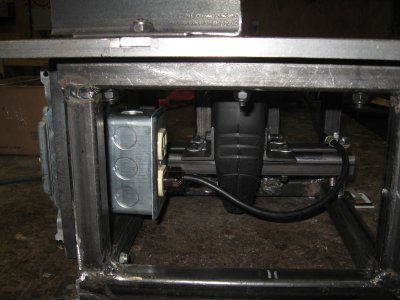

The second pic shows the spring-loaded bottom support pieces, clamps & body support bolt. The clamps & body support are padded to protect the plastic saw body. I have the duplex outlet that the saw is plugged into split up so that the saw is fed from the power switch & the top section is hot continuously so I can use it for a work lamp. Another feature that's not obvious here is that the clamps abut the frame at the back of the fixture to help the saw withstand the thrust against it when cutting.

The first pic shows the table top mostly. I'd like to say I did all the machining here but, alas, I don't have a Blanchard or Mattison surface grinder to clean up the surface & my LMS 3960 Mini MIll had neither the length of cut nor throat capacity to square it up or do the other necessary work so I took it to a local machine shop after I did the design & layout. I was able to drill all the holes, elongate some & mill all the frame pieces to length, however.

The second pic shows the spring-loaded bottom support pieces, clamps & body support bolt. The clamps & body support are padded to protect the plastic saw body. I have the duplex outlet that the saw is plugged into split up so that the saw is fed from the power switch & the top section is hot continuously so I can use it for a work lamp. Another feature that's not obvious here is that the clamps abut the frame at the back of the fixture to help the saw withstand the thrust against it when cutting.