Thank you!

When looking for an Eifel, I personally like the EIfel FLASH (says it right on it) b/c the jaws are a heavier metal than the newer models. New being relative term. I also suggest getting one of the smaller pairs as well.

If I was looking for one al over again, I would make sure I got one that had the normal jaw, the pipe wrench jaw, and the spreader jaw at least. They are worth the extra money it will cost on eBay than when someone sells just the typical Eifel with regular jaw. After using mine so much, I would gladly pay 50.00+ if I did not habve mine already and that was the only one I could find.

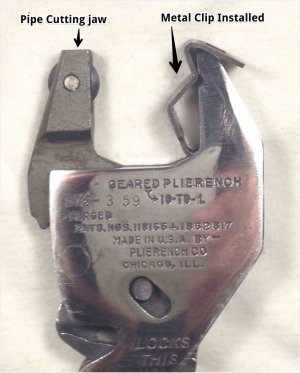

I have never had to use my pipe cutting jaw (and small metal clip that comes with it). And I have only used the wire bending jaw/spring maker a few times.

Uses: easier to describe a scenario than to try to list them all.

Just imagine ALL jobs you do with pliers - you have to squeeze the handles and also apply pressure to do the work you want to do. Such as removing a screw where the head has snapped off. You have to squeeze the handles to keep the pliers clamping what the exposed shank while trying to twist the screw out.

Oh...you wouldn't use pliers for this? I don't blame you. But with the Eifel, you are not squeezing the handles together. You are just holding them there so all the power you put into the job can be used to twist the screw shank out backwards. Yes...I have...many times

If you can get a grip on something, the plierench can get it out for you.

The tool makes the most sense when you actually understand how the mechanism operates. You have the right handle built with a gear head at the top (inside the mechanism) and that gear head meshes into a gear rack on the bottom edge of the moveable jaw.

With a normal set of pliers, the torque you apply (like undoing a stuck nut/bolt) is transferred by a stuck item back through the handles back to your hands. the entire scenario becomes a war of your grip vs. the amount of resistance to moving the stuck item has.

Once you have the rack and gear meshed where you want them to hold the nut/bolt head, there is no way that nut can push those handles apart b/c it is not fighting your grip. Any resistance the nut can give is now fighting a locked gear system instead of your muscles.

When the Eifel clamps, it says it has 1 ton of gripping pressure. So a rounded off nut typically doesn't stand a chance, again with the added benefit that all you are doing is holding the handles instead of trying to squeeze them tight together.

If I am de-rusting a part/bolt/nut with a bench grinder's wire wheel, there is no way the wire wheel can rip the part out of the one ton grip. With pliers if I push too hard against the wire wheel, the part can easily go flying.

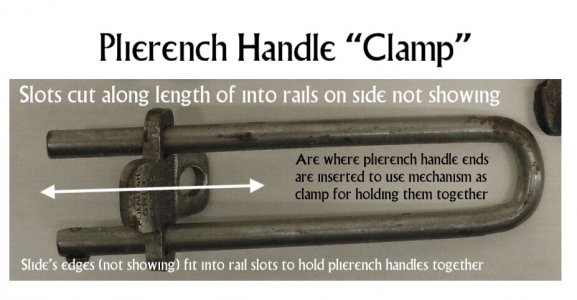

In fact sometimes I just use a rubber band to hold one plierench closed and use it like a small vise.

B/c of that grip you also can get some incredible leverage. Try bending a heavy spike into a loop with e normal pair of pliers and you break your hand. Since you are not squeezing the Eifel tightly, you can get more leverage and bend the nail - no it still takes effort, you can make a loop in the end of the nail.

There IS a learning curve...that takes about 5 seconds. And I think that is why these are not in everyone's toolbox where they would save a lot of effort and time. People just assume they work like regular pliers and get frustrated b/c they cannot get the to clamp by just moving the handles together.

Just like people nowadays are going nuts over the two step operation of Knipex pliers (push button and set the jaws), I like my Eifel (push handle and set the jaws).

These are my go to tool now and have been for awhile. I find if I am using something else I wonder why I didn't use my plierench instead b/c the job would have been easier with less effort.

Oh...once the jaw is set, and let's say you are loosening a nut. Hold the handles together on the power stroke, release the bottom handle on the reset stroke, and the wrench's jaw will now be loose allowing to shift position on the nut...but the correct distance for the gears to mesh inside is not lost. So as soon as you hold the handles together again, for the next power stroke, your one ton grip is there again. It's like a built in ratcheting action.

One other thing...I did learn that some of the older ones have straight gear teeth on the bottom of the removable jaws and some have angled teeth. So the jaws are not always interchangeable from one plierench to another. So if you buy one and then plan to buy the jaws separately, this is a good, and undocumented as far as I have seen, thing to know.

Sorry for the book! My wife get's tired of hearing me say, Man I wish I would have known about these years ago," almost every time I use them!