-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunrunner you need to order a set of these for the Z axis hand crank. Bill did you just spit coffee on your monitor? :rofl:

View attachment 253356

View attachment 253356

H

Hukshawn

Forum Guest

Register Today

As a matter of fact, one of the bolts the igaging dro comes with fits perfectly! And it has a nut. Well, I'll be dammed. That was easy.

Last night, I overlooked a chip guard when mounting that x scale... gonna have to take it all back off, lol. I have some 25 awg aluminum I've been making guards out of. I'll just bend a 90* and screw it on behind the scale. Should be just enough room.

Last night, I overlooked a chip guard when mounting that x scale... gonna have to take it all back off, lol. I have some 25 awg aluminum I've been making guards out of. I'll just bend a 90* and screw it on behind the scale. Should be just enough room.

H

Hukshawn

Forum Guest

Register Today

I have a tendency to do things sometimes to get them done. Then work with it for a while and change it down the road when there's more time/money/desire. I may very well find myself changing the scale position if I need that extra 3/4" travel.I couldn't afford to lose the X axis travel (there's not much there to begin with), so I mounted the scale in front as in the pic. I can still get to the gib adjusters. Replaced the X axis locking lever with a socket head cap screw and use a screwdriver-style allen key when I need to lock it.

It's been like this for over a year of regular use and I haven't had any problems.

The belt drive is a must-do. Makes the machine much smoother and quieter.

The belt drive is definitely something I'd like. Most of my purchases are cash purchases. Try to keep things off the credit cards as that flusters the wardens feathers. And the belt drive is an online purchase. No one around my neck of the woods supplies such a thing. In fact, I called busy bee (where I purchased the mill) to inquire about the belt drive... then the metal gears... then finally replacement plastic ones. (which they don't stock)... they had never heard of the conversion kit, and don't suply the metal gears.

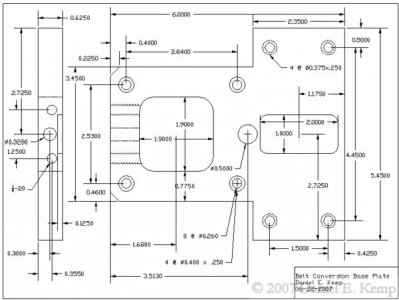

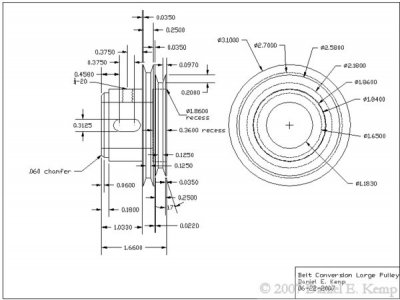

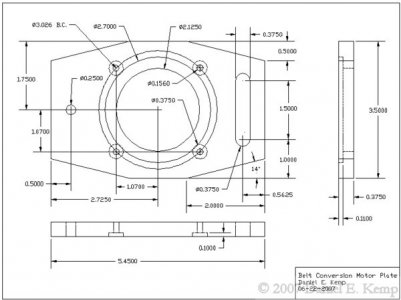

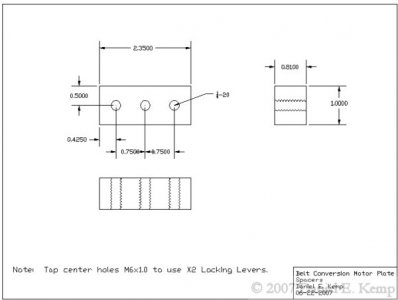

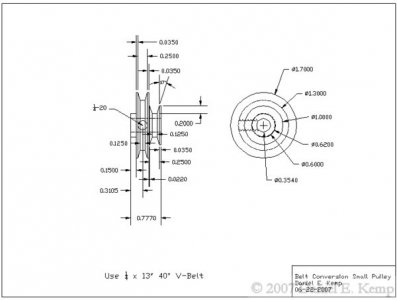

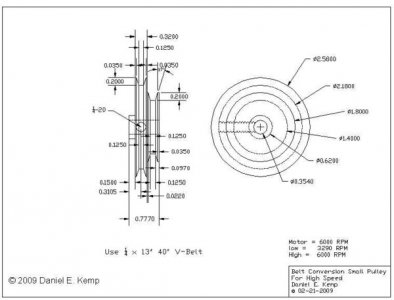

The belt drive conversion kit isn't something that appears to be out of the realm of possibilities to make, even... just a couple pulleys, a mounting bracket, and a floating motor mount. And I'm sure I can find a suitable belt.

Edit: anyone wanna do up a layout with measurements of the pulleys and plates?? I wonder if I look long enough online if I'll find one.

H

Hukshawn

Forum Guest

Register Today

Well now... that's just spectacular. It'll take me a month of Sundays, but that doesn't look impossible. It does, however, look like the bigger parts will move around the vise/table 100 times cause the machine is so small. But that should be fun to screw up 3 times before getting right!!

Last edited by a moderator:

H

Hukshawn

Forum Guest

Register Today

just doesn't show the clear guard. Which, I'm sure I'd ignore till I had a close call then actually look into making.

H

Hukshawn

Forum Guest

Register Today

Why are there two smaller pulleys?

- Joined

- Aug 23, 2014

- Messages

- 932

The belt guard could be made from plexiglass. I don't know if the parts shown are exactly the same as the LMS belt drive but they have all the needed dimensions. You could modify to suit yours needs and machines. It does look like a heck of a lot of work though. That's why I went with the LMS kit. I know you are paying more with high shipping cost since you live in Canada so it might be less expensive to get the materials local to you. Be great if you had someone local with a big mill to knock out the machine work. All doable on the mini mill just a lot slower. Of course you need to add in the extra material for 4 tries or if you were me 6 tries. We need a way to be able to purchase and sell between our 2 county's as though we were one.

If you have the metal internal gears the only one plastic is the intermediate gear on top. This acts like a fuse. I'm sure we could purchase a couple here from LMS and send them to you.

Roy

If you have the metal internal gears the only one plastic is the intermediate gear on top. This acts like a fuse. I'm sure we could purchase a couple here from LMS and send them to you.

Roy

H

Hukshawn

Forum Guest

Register Today

Oh right... that gear kit only comes with two internal gears... huh... didn't realize that. But, it's bigger, thicker, likely less prone to breakage.

My metal supply shop isn't far, 20 mins away on a bad traffic day, and is reasonably priced. The flat plate alumunum might cost me $25 and I could either buy the square stock or just use round stock, which I have, for the spacers. Really, the belt might be the only tricky purchase.

And yes, the difference in dollar and shipping is painful, most of the time.

My metal supply shop isn't far, 20 mins away on a bad traffic day, and is reasonably priced. The flat plate alumunum might cost me $25 and I could either buy the square stock or just use round stock, which I have, for the spacers. Really, the belt might be the only tricky purchase.

And yes, the difference in dollar and shipping is painful, most of the time.