Rex,

Stepper motors are brushless, so the use energized poles to move the rotor. I would suggest that you read a document on steppers called "Jones on Steppers" available all over the web and at the Univ of Iowa site also. The number of poles in a stepper determines the resolution that you can gain by lessening the movement of the rotor for each energized pole. Once you have read the article on steppers and still have questions do not hesitate to ask and we will get you turned the right was pretty easilly.

Bob

Thanks for the reference. I'll spend some time with that. I have some small knowledge of steppers, and a book called "Easy Step'n", but had not run across any 5 phase steppers before, and was unaware of their existence. I bought these motors a year ago, and found little info then, however, after posting this I googled and found more info, much of it referring to a motor with 5 wires.

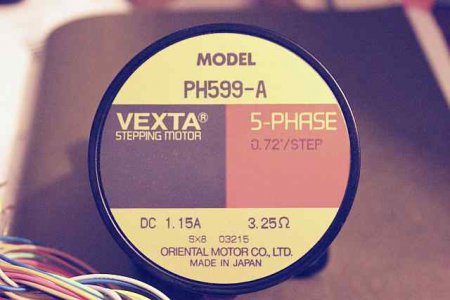

This motor is a VEXTA Model PH599-A, 5-Phase, .72"/step, DC 1.15A, 3.25ohm. Below those specs: SX8 03215 ORIENTAL MOTOR CO., LTD, Made in Japan. Picture to follow

Rex