4

4GSR

Forum Guest

Register Today

Could you not surface grind a step on the bottom of the scriber to compensate for the .040"? Maybe I'm looking this wrong...

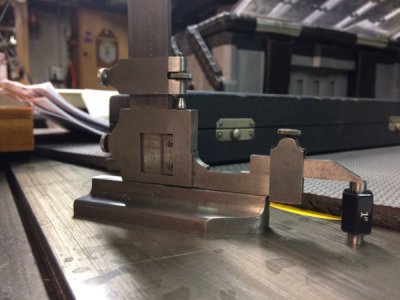

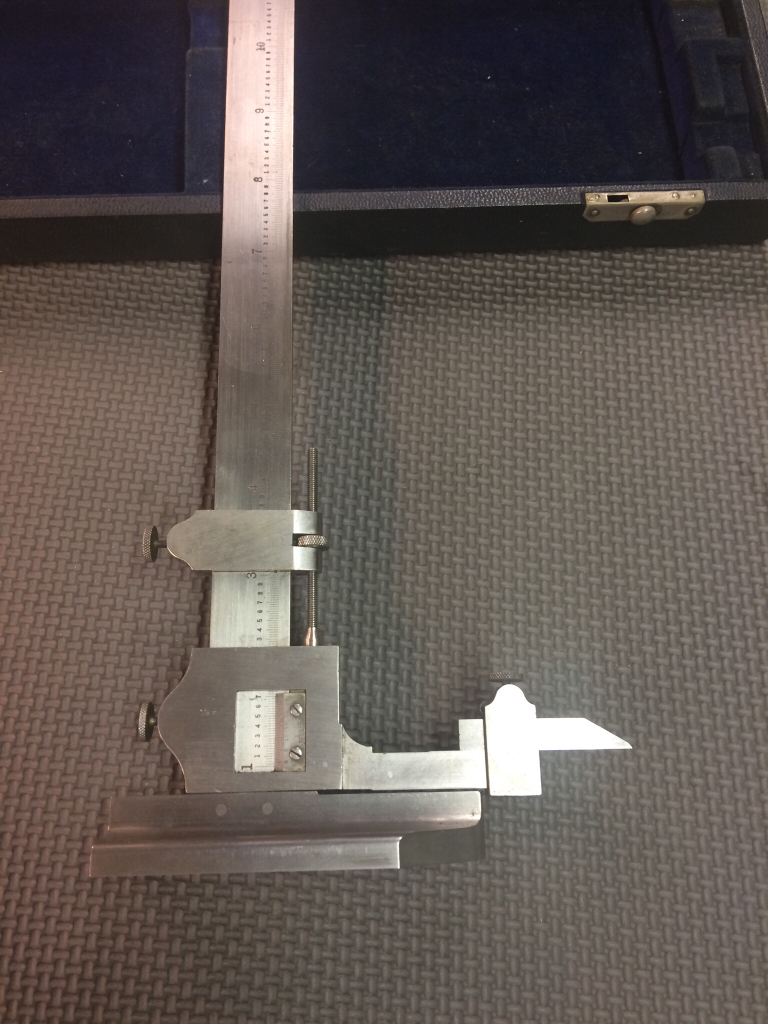

Just for grins, I pulled out my nearly new Starrett height gage, set it up on the surface plate, and sure enough, the scriber sets on top of the slide. Checking it against a 1" gage block, it's right on!

Funny, my MTI surface gage, the offset scriber rest on the bottom side of the slide.

Just for grins, I pulled out my nearly new Starrett height gage, set it up on the surface plate, and sure enough, the scriber sets on top of the slide. Checking it against a 1" gage block, it's right on!

Funny, my MTI surface gage, the offset scriber rest on the bottom side of the slide.