I make numbered brass tags which I sell to antique auto enthusiasts. These were used in the 1940's, 50's and 60's to identify cars built in England. These are made with an antique embossing machine. The brass stock that I have been buying is cartridge brass and comes to me in strips that are .875 wide and 36 inches long and .016 thick. The finished tags are usually 3 - 3.5 inches long and the strip stock is .875 wide. I need to devise something to trim the ends of the brass tags to produce a neat, near perfect radius. Or, in other words I want to round off the ends to a perfect semi-circle. I've been thinking about this for some time and I guess I would need some sort of trimming die with a semicircular profile. So, I think I know what I need. Now, I need some help to make it.

Maybe you have a suggestion!

Thanks, Frank

p.s.

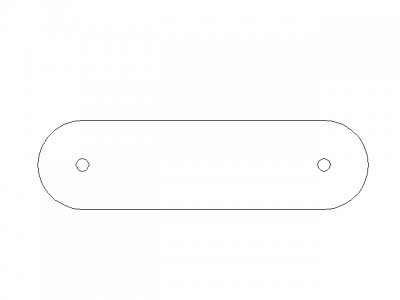

This is what the tags look like out of the machine, including equally spaced mounting holes. However, as you can see, the ends are not quite round.

Maybe you have a suggestion!

Thanks, Frank

p.s.

This is what the tags look like out of the machine, including equally spaced mounting holes. However, as you can see, the ends are not quite round.