- Joined

- Nov 14, 2014

- Messages

- 851

Hello all,

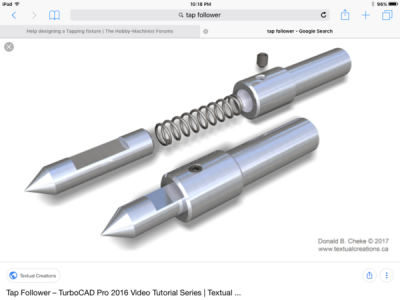

I guess it’s time to make an alignment tool or fixture to set up in the quill of a mill to align taps at 90* to the work, when you first start to twist the tap into the hole. Anybody have a link to a thead or set of diagrams about how to build such a thing?

Now, am not talking about taping heads, or standalone taping machines, Just some simple alignment tool to help orient the tap when hand tapping.

I remember someone made some sort of spring fed device that kept pressure on the top of the tap, but of course can’t find it with any words I could think,of in the search bar.

Any leads would be greatly appreciated!

Thanks

Glenn

I guess it’s time to make an alignment tool or fixture to set up in the quill of a mill to align taps at 90* to the work, when you first start to twist the tap into the hole. Anybody have a link to a thead or set of diagrams about how to build such a thing?

Now, am not talking about taping heads, or standalone taping machines, Just some simple alignment tool to help orient the tap when hand tapping.

I remember someone made some sort of spring fed device that kept pressure on the top of the tap, but of course can’t find it with any words I could think,of in the search bar.

Any leads would be greatly appreciated!

Thanks

Glenn