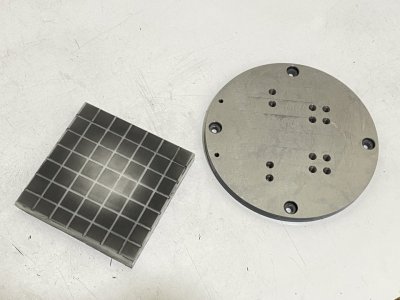

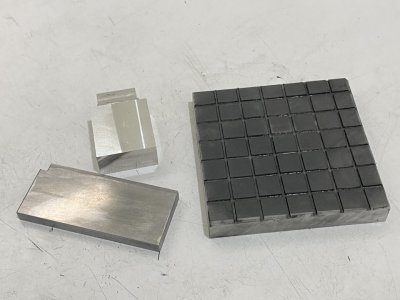

Today I tried diamond lapping for the first time on the hole plate I have made for my rotary table. The lap is a piece of HDPE plastic and the hole plate is hot-rolled steel. All went well and the lapped surface appears to be quite flat. No dishing or rounding off near the edge.

However, it appears that the lapped surface is now embedded with diamond particles ( 40 micron according to the vendor ). If I rub a piece of steel against the surface, very fine scratch lines will be formed and I could feel that some abrasion is happening. Some of the diamond particles seems to have transferred to the milling table as well. How should I go about to clean it up completely ? Thanks in advance.

However, it appears that the lapped surface is now embedded with diamond particles ( 40 micron according to the vendor ). If I rub a piece of steel against the surface, very fine scratch lines will be formed and I could feel that some abrasion is happening. Some of the diamond particles seems to have transferred to the milling table as well. How should I go about to clean it up completely ? Thanks in advance.

Attachments

Last edited: